Page 214 -

P. 214

HIGH-RATE GRANULAR MEDIA FILTRATION 8.33

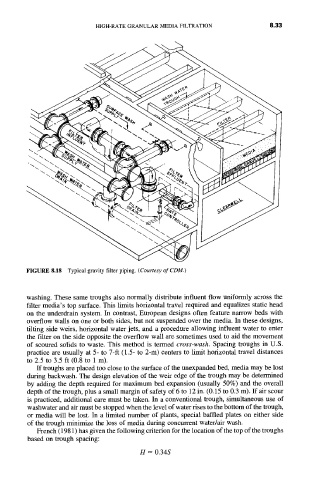

FIGURE 8.18 Typical gravity filter piping. (Courtesy of CDM.)

washing. These same troughs also normally distribute influent flow uniformly across the

filter media's top surface. This limits horizontal travel required and equalizes static head

on the underdrain system. In contrast, European designs often feature narrow beds with

overflow walls on one or both sides, but not suspended over the media. In these designs,

tilting side weirs, horizontal water jets, and a procedure allowing influent water to enter

the filter on the side opposite the overflow wall are sometimes used to aid the movement

of scoured solids to waste. This method is termed cross-wash. Spacing troughs in U.S.

practice are usually at 5- to 7-ft (1.5- to 2-m) centers to limit horizontal travel distances

to 2.5 to 3.5 ft (0.8 to 1 m).

If troughs are placed too close to the surface of the unexpanded bed, media may be lost

during backwash. The design elevation of the weir edge of the trough may be determined

by adding the depth required for maximum bed expansion (usually 50%) and the overall

depth of the trough, plus a small margin of safety of 6 to 12 in. (0.15 to 0.3 m). If air scour

is practiced, additional care must be taken. In a conventional trough, simultaneous use of

washwater and air must be stopped when the level of water rises to the bottom of the trough,

or media will be lost. In a limited number of plants, special baffled plates on either side

of the trough minimize the loss of media during concurrent water/air wash.

French (1981) has given the following criterion for the location of the top of the troughs

based on trough spacing:

H = 0.34S