Page 443 -

P. 443

13.40 CHAPTER THIRTEEN

For EDR systems, recovery is lowered somewhat by discharge of concentrate off-

specification water immediately after polarity reversal when the concentrate compartments

become the dilute (demineralized) water compartments.

System recovery is also affected by electrical water transfer. Typically 0.5% of de-

mineralized stream flow passes through to the concentrate stream per 1,000 mg/L TDS

removed electrically (not hydraulically) along with ions (MeUer, 1984).

Solute Removal. The following factors affect solute removal of an ED/EDR system.

Desalination Ratio. Salt removal in an ED/EDR system is directly proportional to

current flow across the stack. Typically, TDS is concentrated about 3.0 to 3.6 times (i.e.,

the desalination ratio) in a single pass through the system (Wolfe, 1993). The desalina-

tion ratio varies with different membrane types and varying ions. For instance, the de-

salination ratio may be as high as 10 to 1 for nitrate and only 1.5 to 1 for sulfate using

monovalent selective membranes (Wolfe, 1993).

Limiting Current Density. There is a limit to the rate at which ions can be transferred

through an ED/EDR membrane. Polarization occurs when too few ions are present to al-

low proper current flow and the resulting high electrical resistance causes water mole-

cules to split. Typically, 70% of the limiting current density is used as the maximum de-

sign value.

Current Leakage. There is also a limit to the voltage that can be applied to an ED/EDR

membrane stack. At that limit, excessive electric current leaks through an adjacent mem-

brane to the concentrate stream, causing heat and resulting in damage. Maximum design

voltage is typically 80% of the voltage where current leakage occurs.

Back Diffusion. If the concentrate is too concentrated, ions can diffuse (against the

force of the dc potential) back to the demineralized stream. Typical design practice low-

ers membrane stack efficiency when the concentration of the concentrate exceeds 150%

of the concentration in the demineralized stream.

Types of Membranes. A number of membrane products are available. Some mem-

branes are designed to maximize specific ions, such as monovalent-specific membranes

that do not concentrate calcium sulfate as much as conventional membranes. This may

allow higher recovery operation, if calcium sulfate solubility is the limiting criterion.

Temperature. Temperature is one of the most important factors affecting ion removal.

Ion removal increases about 2% per degree Celsius temperature rise.

Product Water Quality. Because electrical resistance increases as the demineralized

stream becomes more and more dilute, ED/EDR systems often are designed to limit dem-

ineralized flow streams to a minimum of about 200 mg/L (although lower concentrations

are possible).

Power Consumption. Power is required for pumping power and current flow across

membrane stacks. The pumping power for a single-pass system can be estimated, assuming

a flow rate of about 1.3 times the feed flow rate (for dilute and concentrate), and the pres-

sure loss through the stack at about 50 psi (340 kPa).

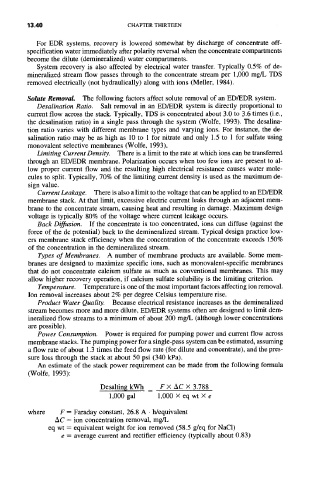

An estimate of the stack power requirement can be made from the following formula

(Wolfe, 1993):

Desalting kWh = F X AC X 3.788

1,000 gal 1,000 X eq wt X e

F = Faraday constant, 26.8 A • h/equivalent

where

AC = ion concentration removal, mg/L

eq wt = equivalent weight for ion removed (58.5 g/eq for NaC1)

e = average current and rectifier efficiency (typically about 0.83)