Page 456 -

P. 456

14.4 CHAPTER FOURTEEN

The uniformity coefficient is a ratio of the size opening that will pass 60% of a rep-

resentative sample of the filter material to the size opening that will pass just 10% of the

same sample. The maximum uniformity coefficient recommended by AWWA is 2.1 af-

ter backwashing and draining a GAC filter. If two types of GAC media have the same

effective size, the one with a larger uniformity coefficient (that is, 1.7 to 2.4) will have a

greater number of fines in the upper layers of a stratified bed and larger particles in the

lower layers. Typical uniformity coefficients for GAC produced in the United States are

less than or equal to 1.9.

Manufacture of Activated Carbon

Activated carbon is made from organic materials having a high carbon content. A wood

product such as sawdust, coconut shells, or wood may be used, or a coal product such as

bituminous coal, lignite, or peat is converted to activated carbon by heating the material

to between 300 ° and 1,000 ° C. The resulting carbon material provides large surface ar-

eas and, accordingly, a large number of adsorption sites.

DESIGN OF POWDERED ACTIVA TED

CARBON FACILITIES

PAC is used by surface water treatment plants either full-time or as needed for taste and

odor control or removal of organic chemicals.

Characteristics of PAC

The apparent density of PAC ranges from 23 to 46 lb/ft 3 (0.36 to 0.74 g/cm 3) depending on

the type of material and the manufacturing process. Iodine and molasses numbers are often

used to characterize PAC. Information needed to evaluate different PACs is shown in Table

14.1, which summarizes the manufacturers' specifications for some commercially available

PACs. In general, the following criteria should be used to evaluate different PACs:

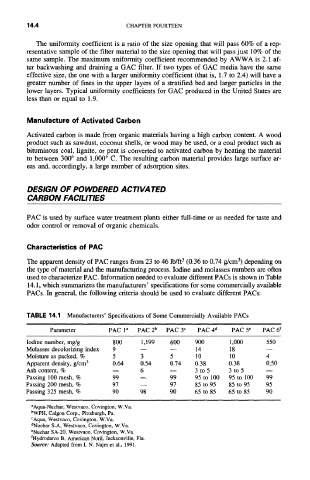

TABLE 14.1 Manufacturers' Specifications of Some Commercially Available PACs

Parameter PAC I a PAC 2 b PAC 3 c PAC 4 d PAC 5 e PAC 6 f

Iodine number, mg/g 800 1,199 600 900 1,000 550

Molasses decolorizing index 9 -- -- 14 18 --

Moisture as packed, % 5 3 5 10 10 4

Apparent density, g/cm 3 0.64 0.54 0.74 0.38 0.38 0.50

Ash content, % -- 6 -- 3 to 5 3 to 5 --

Passing 100 mesh, % 99 -- 99 95 to 100 95 to 100 99

Passing 200 mesh, % 97 -- 97 85 to 95 85 to 95 95

Passing 325 mesh, % 90 98 90 65 to 85 65 to 85 90

aAqua-Nuchar, Westvaco, Covington, W.Va.

bWPH, Calgon Corp., Pittsburgh, Pa.

CAqua, Westvaco, Covington, W.Va.

dNuchar S-A, Westvaco, Covington. W.Va.

eNuchar SA-20, Westvaco, Covington, W.Va.

fHydrodarco B, American Noril, Jacksonville, Fla.

Source: Adapted from I. N. Najm et al., 1991.