Page 486 -

P. 486

14.34 CHAPTER FOURTEEN

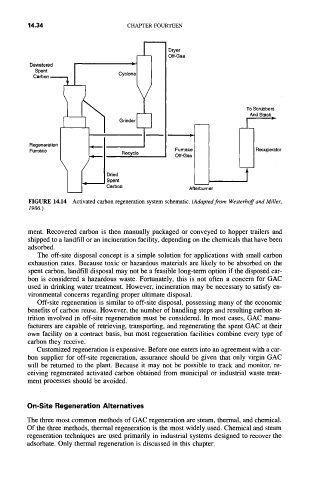

m

Dryer

Dewatered I 2e 1 O.-Gas

Spent Cycle

Carbon

To Scrubbers

And Stack

Grinder ~

ET-or

RegeneratiOnFumace "<'" Fu~mace

Recycle Off-Gas

Dried

Spent

Carbon Afterburner

FIGURE 14.14 Activated carbon regeneration system schematic. (Adapted from Westerhoffand Miller,

1986.)

ment. Recovered carbon is then manually packaged or conveyed to hopper trailers and

shipped to a landfill or an incineration facility, depending on the chemicals that have been

adsorbed.

The off-site disposal concept is a simple solution for applications with small carbon

exhaustion rates. Because toxic or hazardous materials are likely to be absorbed on the

spent carbon, landfill disposal may not be a feasible long-term option if the disposed car-

bon is considered a hazardous waste. Fortunately, this is not often a concern for GAC

used in drinking water treatment. However, incineration may be necessary to satisfy en-

vironmental concerns regarding proper ultimate disposal.

Off-site regeneration is similar to off-site disposal, possessing many of the economic

benefits of carbon reuse. However, the number of handling steps and resulting carbon at-

trition involved in off-site regeneration must be considered. In most cases, GAC manu-

facturers are capable of retrieving, transporting, and regenerating the spent GAC at their

own facility on a contract basis, but most regeneration facilities combine every type of

carbon they receive.

Customized regeneration is expensive. Before one enters into an agreement with a car-

bon supplier for off-site regeneration, assurance should be given that only virgin GAC

will be returned to the plant. Because it may not be possible to track and monitor, re-

ceiving regenerated activated carbon obtained from municipal or industrial waste treat-

ment processes should be avoided.

On-Site Regeneration Alternatives

The three most common methods of GAC regeneration are steam, thermal, and chemical.

Of the three methods, thermal regeneration is the most widely used. Chemical and steam

regeneration techniques are used primarily in industrial systems designed to recover the

adsorbate. Only thermal regeneration is discussed in this chapter.