Page 492 -

P. 492

15.2 CHAPTER FIFTEEN

For chemicals in solution form:

8.34 lb/gal X dosage (mg/L) X flow (mgd) x 100%

Feed rate (gal/h) =

24 h x concentration (%) x density (lb/gal)

Chemical storage or inventory requirements can be computed from feed rates and the

number of days of storage required.

Capacities and Feed Rates. Many different conditions must be evaluated to determine

the range of feed rates used to select feed equipment capacities for each chemical. For an

existing treatment plant, or where there is another plant using the same water source, his-

torical records should be investigated to obtain peak- and minimum-hour dosages for the

plant's chemicals. For a new plant without records, bench- and pilot-scale testing is re-

quired. Table 15.1 provides guidelines for chemical feed and storage capacities, but these

guidelines should be integrated with consideration to regional and state standards, oper-

ating records of similar plants, and experience.

Minimum feed rate capacities and the feed equipment's capability to accurately feed

at low rates are as important as maximum capacities. Once dosage and feed rates are cal-

culated, these usually must be adjusted upward to account for chemical purity or percent

availability for reaction.

Sizing the Inventory. Inventory size is based on factors that vary from plant to plant,

even within the same system. First, determine the maximum monthly feed rate of the

chemical, accounting for dosage and plant flow rate. Second, the appropriate number of

days of chemical storage should be established for each chemical, typically between 7 and

30 days. Major considerations include the general availability of the chemical, location

of chemical suppliers, reliability of suppliers during periods of shortage, normal delivery

time, and delays in shipment that may be caused by weather conditions. Another consid-

eration is the possibility of delays in receiving shipments because of transportation strikes

or natural or human-caused emergencies. Some state regulatory agencies specify a mini-

mum number of days for certain chemicals.

Once the number of days of storage for each chemical has been identified, it is possi-

ble to determine whether bulk deliveries are practical. In smaller plants using bulk deliv-

ery chemicals, the quantity stored may be dictated more by the size of the bulk shipping

containers in use in the area than by the desired number of days' supply. Many regula-

tors require minimum storage requirements equal to 1.5 truckloads of a bulk delivery.

Excess inventory is undesirable if the chemical has a limited shelf life. Chemicals such

as soda ash and quicklime that either possess hygroscopic properties or are otherwise af-

fected by moisture can become difficult to handle after several months in bulk storage

unless precautions are taken to control the environment. Chemicals furnished in return-

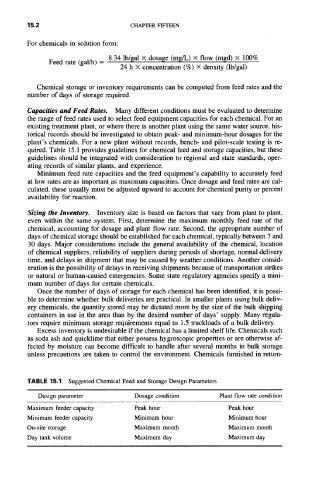

TABLE 15.1 Suggested Chemical Feed and Storage Design Parameters

Design parameter Dosage condition Plant flow rate condition

Maximum feeder capacity Peak hour Peak hour

Minimum feeder capacity Minimum hour Minimum hour

On-site storage Maximum month Maximum month

Day tank volume Maximum day Maximum day