Page 500 -

P. 500

15.10 CHAPTER FIFTEEN

provided the same chemical is being handled, but under no circumstances should a mix-

ture of different chemical dusts be allowed to accumulate within one collector. A dust

collector' s size depends on the volume of air to be handled. Air blowers mounted on pneu-

matic trucks commonly have the capability of producing up to 750 ft3/min (21 m3/min)

of air.

Bag filters work for most dust collection applications, but vortex scrubbers should be

considered for powdered activated carbon slurry tanks. The unloading rate for carbon into

a slurry tank potentially could overwhelm a bag filter and require excessive maintenance.

Properly specified vortex scrubbers can provide adequate removal of carbon dust with rel-

atively minimal maintenance. When mounted on top of the carbon slurry tank, vortex

scrubbers operate with a water spray entering near the top and traveling countercurrently

to the carbon-laden air entering from the bottom. Water and trapped carbon discharge di-

rectly into the slurry tank.

Delivery, Handling, and Storage of Liquid Chemicals. Some of the chemicals most

commonly used in liquid form in water treatment are listed in Table 15.2. When one is

computing storage and feed rate requirements, the effective density must be used. The ef-

fective density is determined by the bulk density, active component of the chemical mol-

ecule, and solution strength, as shown in the table.

Liquid chemicals, such as caustic soda, liquid alum, acids, or corrosion inhibitors, are

generally delivered by tank truck. To facilitate safe unloading, it is the user's responsi-

bility to provide appropriate fill-pipe connections, clearly labeled and equipped with pro-

tective caps. A concrete drip sump protected with a chemically resistant coating should

be provided beneath all fill-pipe connections.

Local and state regulations may require secondary containment for the entire unload-

ing area. Storage tank overflow pipes should terminate into the secondary containment.

If the stored chemical has fuming or corrosive properties, the overflow must be sealed

with a vapor check valve.

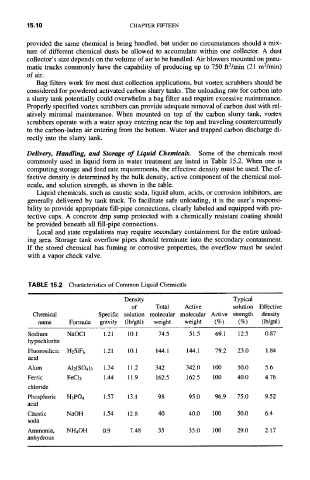

TABLE 15.2 Characteristics of Common Liquid Chemicals

Typical

Density

of Total Active solution Effective

Specific solution molecular molecular Active strength density

Chemical

name Formula gravity (lb/gal) weight weight (%) (%) (lb/gal)

Sodium NaOC1 1.21 10.1 74.5 51.5 69.1 12.5 0.87

hypochlorite

Fluorosilicic HzSiF6 1.21 10.1 144.1 144.1 79.2 23.0 1.84

acid

342.0 100 50.0 5.6

Alum A12(SO4)3 1.34 11.2 342

Ferric FeC13 1.44 11.9 162.5 162.5 100 40.0 4.76

chloride

95.0 96.9 75.0 9.52

Phosphoric H3PO4 1.57 13.1 98

acid

Caustic NaOH 1.54 12.8 40 40.0 I00 50.0 6.4

soda

35.0 100 29.0 2.17

Ammonia, NH4OH 0.9 7.48 35

anhydrous