Page 503 -

P. 503

CHEMICALS AND CHEMICAL HANDLING '15.'13

ride (CPVC), 3-in. (80-ram) diameter, as a precaution. Plug, needle-and-ball valves, 150-

lb integral flanges with PVC or type 316 stainless steel construction, and tetrafluoroeth-

ylene (TFE) or similar material sleeves or retaining rings are recommended. A schematic

layout of an alum feed system is shown in Figure 15.3.

Caustic Soda Storage. Liquid caustic soda is delivered by railcar and tanker truck.

Tanker trucks can haul up to 3,000 gal (11,400 L) per load. Storage tanks should be con-

structed of stainless steel, FRP, polyethylene, or steel lined with rubber or polypropylene.

As with alum, schedule-80 PVC with socket end joints is the recommended piping ma-

terial if liquid temperatures do not exceed 120 ° F (49 ° C). Caustic soda generates heat

when mixed with water, resulting in temperatures approaching this level, so use of CPVC

piping should be considered for this application. Valves can be steel or ductile iron with

Teflon components, rubber-lined, or PVC.

The freezing point of caustic soda solution is highly dependent on the solution strength

(Figure 15.4). Freezing points for solutions greater than 50% quickly elevate, making it

impractical to handle and store. Because 50% caustic soda begins to crystallize at ap-

proximately 54 ° F (12 ° C), storage tanks must be indoors or insulated and heated to avoid

crystallization. A typical chemical feed schematic for caustic soda appears in Figure 15.5.

Sodium Hypochlorite Storage. Commercial sodium hypochlorite (NaOC1), or liquid

bleach, is marketed in carboys and rubber-lined drums holding up to 50-gal (190-L) vol-

ume, and in trucks. Storage tanks should be constructed of FRP, polyethylene, or steel

lined with rubber or polypropylene. As with alum, schedule-80 PVC with socket end joints

is the recommended piping material if liquid temperatures do not exceed 120 ° F (49 ° C).

Valves may be a plug type made of steel (lined with PVC or polypropylene), or PVC

diaphragm valves. Although PVC ball valves would not react with the chemical, hypochlo-

rite releases small amounts of gas as it decomposes, and PVC ball valve failures due to

gas buildup have been reported. A similar type of failure has occurred with stainless steel

(SST) ball valves in hydrogen peroxide service. Any type of ball valve, especially 1-in.

and larger sizes, may allow hypochlorite to weep through the seal and crystallize. To avoid

these problems, a diaphragm valve constructed of composite material using a Teflon di-

aphragm can be used.

When hypochlorite is added to water, it hydrolyzes to form hypochlorous acid (HOC1),

the same active ingredient that occurs when chlorine gas is used. The hypochlorite reac-

tion slightly increases the hydroxyl ions (pH increase) by the formation of sodium hy-

droxide, whereas the reaction of chlorine gas with water increases the hydrogen ion con-

centration (pH decrease), forming hydrochloric acid. In most waters, these differences are

not significant, but when high chlorine doses are used in poorly buffered waters, these ef-

fects should be considered. They can be evaluated by calculation or by simple laboratory

tests.

In the commercial trade, the concentration of sodium hypochlorite solutions is usually

expressed as a percentage. The trade percent is actually a measure of weight per unit vol-

ume, with 1% corresponding to a weight of 10 g of available chlorine per liter. Common

household bleach, at a trade concentration of 5.25%, has approximately 5,25 g/100 mL

or 52.5 g/L of available chlorine. Hypochlorite available for municipal use usually has a

trade concentration of 12.5% to 17%. These are approximate concentrations and should

always be confirmed by laboratory procedures.

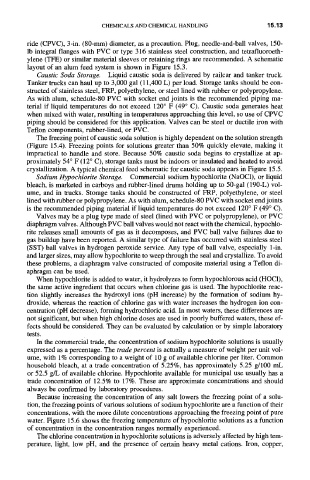

Because increasing the concentration of any salt lowers the freezing point of a solu-

tion, the freezing points of various solutions of sodium hypochlorite are a function of their

concentrations, with the more dilute concentrations approaching the freezing point of pure

water. Figure 15.6 shows the freezing temperature of hypochlorite solutions as a function

of concentration in the concentration ranges normally experienced.

The chlorine concentration in hypochlorite solutions is adversely affected by high tem-

perature, light, low pH, and the presence of certain heavy metal cations. Iron, copper,