Page 510 -

P. 510

15.18 CHAPTER FIFTEEN

Gas Feed Equipment

Chlorine and ammonia gases are used in disinfection treatment processes and require care.

ful selection of equipment because of the aggressiveness and dangers associated with the

gases.

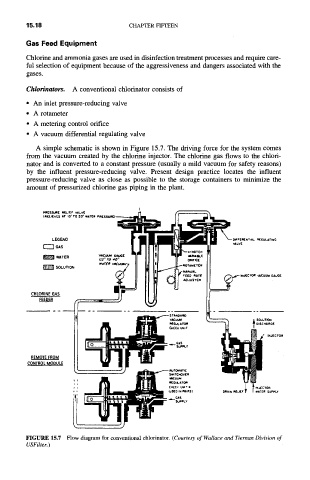

Chlorinators. A conventional chlorinator consists of

• An inlet pressure-reducing valve

• A rotameter

• A metering control orifice

• A vacuum differential regulating valve

A simple schematic is shown in Figure 15.7. The driving force for the system comes

from the vacuum created by the chlorine injector. The chlorine gas flows to the chlori-

nator and is converted to a constant pressure (usually a mild vacuum for safety reasons)

by the influent pressure-reducing valve. Present design practice locates the influent

pressure-reducing valve as close as possible to the storage containers to minimize the

amount of pressurized chlorine gas piping in the plant.

Plq[S.~ua£ nELIEr vALVE

(reEL,IrES *.1" 10" TO 20" WATER

LEGEND

F'--"IGAS

~'~WATER

~SOLUTION

CHLORINE GAS

FEEDER

~..xrc. h l l T =sc..~o,E

CHCCK UNiT ~ ~ ~/ INJ(.CTOR

GAS

5 UlH',.y

REMOTE FROM

CONTROL MODULE

~c

) 0~N ~LEr I wA~[~ ~PLv

FIGURE 15.7 Flow diagram for conventional chlorinator. (Courtesy of Wallace and Tiernan Division of

USFiher.)