Page 81 -

P. 81

4,32 CHAPTER FOUR

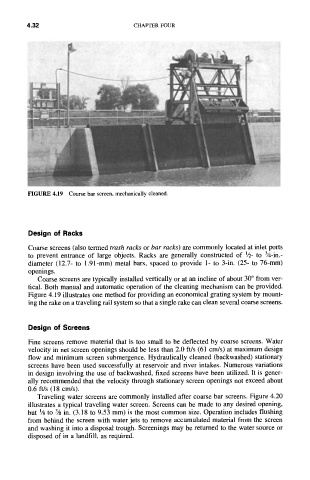

FIGURE 4.19 Course bar screen, mechanically cleaned.

Design of Racks

Coarse screens (also termed trash racks or bar racks) are commonly located at inlet ports

to prevent entrance of large objects. Racks are generally constructed of 1/2- to 3A-in.-

diameter (12.7- to 1.91-mm) metal bars, spaced to provide 1- to 3-in. (25- to 76-mm)

openings.

Coarse screens are typically installed vertically or at an incline of about 30 ° from ver-

tical. Both manual and automatic operation of the cleaning mechanism can be provided.

Figure 4.19 illustrates one method for providing an economical grating system by mount-

ing the rake on a traveling rail system so that a single rake can clean several coarse screens.

Design of Screens

Fine screens remove material that is too small to be deflected by coarse screens. Water

velocity in net screen openings should be less than 2.0 ft/s (61 crn/s) at maximum design

flow and minimum screen submergence. Hydraulically cleaned (backwashed) stationary

screens have been used successfully at reservoir and river intakes. Numerous variations

in design involving the use of backwashed, fixed screens have been utilized. It is gener-

ally recommended that the velocity through stationary screen openings not exceed about

0.6 ft/s (18 cm/s).

Traveling water screens are commonly installed after coarse bar screens. Figure 4.20

illustrates a typical traveling water screen. Screens can be made to any desired opening,

but IA~ to 3/~ in. (3.18 to 9.53 mm) is the most common size. Operation includes flushing

from behind the screen with water jets to remove accumulated material from the screen

and washing it into a disposal trough. Screenings may be returned to the water source or

disposed of in a landfill, as required.