Page 80 -

P. 80

INTAKE FACILITIES 4.31

The choice of chemical treatment to be applied at the intake must be coordinated with

overall optimization of the water treatment process, including the control of disinfection

by-product formation. Historically, chlorine has been used as the standard treatment to

oxidize taste and odor compounds at the intake structure. However, current practice is to

avoid the early use of chlorine in the treatment process where the level of organics in the

source water is highest because of the potential for forming chlorinated disinfection by-

products such as trihalomethanes. Chlorine dioxide, potassium permanganate, and carbon

are alternatives to chlorine that avoid or minimize the formation of chlorinated disinfec-

tion by-products.

RACKS AND SCREENS

Racks and screens remove suspended particulates from water, including leaves, debris,

and other sizable clogging material. Racks and screens are essential to providing protec-

tion for downstream conduits, pumps, and treatment works. Properly designed intake racks

and screens can also minimize the effect on fish.

Racks and screens can be divided into two broad categories: coarse screens (racks)

and fine screens. A summary of characteristics associated with each type is presented in

Table 4.14.

Design Considerations

Head loss through racks and screens is an important consideration to be evaluated as part

of the design process. Racks and screens should be designed to minimize head loss by

providing sufficient flow-through area to keep velocities low. The total area of clear open-

ings in a screen typically ranges between 150% and 200% or more of the area or chan-

nel protected by the screen. The maximum head loss from clogging should be limited to

between 2.5 and 5.0 ft (0.76 and 1.52 m), and the screen should be designed to withstand

the differential hydraulic load. Head loss for mechanically cleaned screens of all types

can be held nearly constant with proper operator attention. Curves and tables for head loss

through screening devices are available from equipment manufacturers.

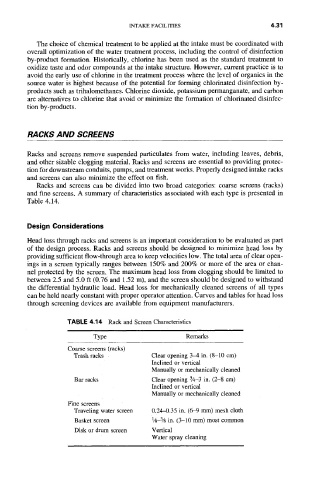

TABLE 4.14 Rack and Screen Characteristics

Type Remarks

Coarse screens (racks)

Trash racks Clear opening 34 in. (8-10 cm)

Inclined or vertical

Manually or mechanically cleaned

Clear opening 3,4-3 in. (2-8 cm)

Barracks

Inclined or vertical

Manually or mechanically cleaned

Fine screens

Traveling water screen 0.24~).35 in. (6-9 mm) mesh cloth

1/~_3/~ in. (3-10 mm) most common

Basket screen

Disk or drum screen Vertical

Water spray cleaning