Page 75 -

P. 75

4.26 CHAPTER FOUR

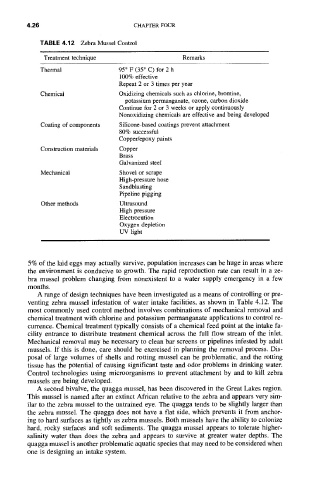

TABLE 4.12 Zebra Mussel Control

Treatment technique Remarks

Thermal 95 ° F (35 ° C) for 2 h

100% effective

Repeat 2 or 3 times per year

Oxidizing chemicals such as chlorine, bromine,

Chemical

potassium permanganate, ozone, carbon dioxide

Continue for 2 or 3 weeks or apply continuously

Nonoxidizing chemicals are effective and being developed

Coating of components Silicone-based coatings prevent attachment

80% successful

Copper/epoxy paints

Construction materials Copper

Brass

Galvanized steel

Mechanical Shovel or scrape

High-pressure hose

Sandblasting

Pipeline pigging

Other methods Ultrasound

High pressure

Electrocution

Oxygen depletion

UV light

5% of the laid eggs may actually survive, population increases can be huge in areas where

the environment is conducive to growth. The rapid reproduction rate can result in a ze-

bra mussel problem changing from nonexistent to a water supply emergency in a few

months.

A range of design techniques have been investigated as a means of controlling or pre-

venting zebra mussel infestation of water intake facilities, as shown in Table 4.12. The

most commonly used control method involves combinations of mechanical removal and

chemical treatment with chlorine and potassium permanganate applications to control re-

currence. Chemical treatment typically consists of a chemical feed point at the intake fa-

cility entrance to distribute treatment chemical across the full flow stream of the inlet.

Mechanical removal may be necessary to clean bar screens or pipelines infested by adult

mussels. If this is done, care should be exercised in planning the removal process. Dis-

posal of large volumes of shells and rotting mussel can be problematic, and the rotting

tissue has the potential of causing significant taste and odor problems in drinking water.

Control technologies using microorganisms to prevent attachment by and to kill zebra

mussels are being developed.

A second bivalve, the quagga mussel, has been discovered in the Great Lakes region.

This mussel is named after an extinct African relative to the zebra and appears very sim-

ilar to the zebra mussel to the untrained eye. The quagga tends to be slightly larger than

the zebra mussel. The quagga does not have a flat side, which prevents it from anchor-

ing to hard surfaces as tightly as zebra mussels. Both mussels have the ability to colonize

hard, rocky surfaces and soft sediments. The quagga mussel appears to tolerate higher-

salinity water than does the zebra and appears to survive at greater water depths. The

quagga mussel is another problematic aquatic species that may need to be considered when

one is designing an intake system.