Page 160 - 3D Fibre Reinforced Polymer Composites

P. 160

Knitted Composite Materials 149

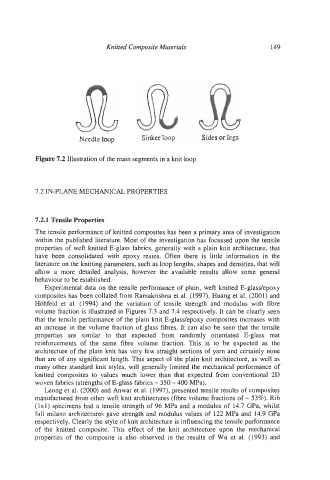

Ncedlc loop Sinker loop Sides or legs

Figure 7.2 Illustration of the main segments in a knit loop

7.2 IN-PLANE MECHANICAL PROPERTIES

7.2.1 Tensile Properties

The tensile performance of knitted composites has been a primary area of investigation

within the published literature. Most of the investigation has focussed upon the tensile

properties of weft knitted E-glass fabrics, generally with a plain knit architecture, that

have been consolidated with epoxy resins. Often there is little information in the

literature on the knitting parameters, such as loop lengths, shapes and densities, that will

allow a more detailed analysis, however the available results allow some general

behaviour to be established.

Experimental data on the tensile performance of plain, weft knitted E-glasdepoxy

composites has been collated from Ramakrishna et al. (1997), Huang et al. (2001) and

Hohfeld et al. (1994) and the variation of tensile strength and modulus with fibre

volume fraction is illustrated in Figures 7.3 and 7.4 respectively. It can be clearly seen

that the tensile performance of the plain knit E-glass/epoxy composites increases with

an increase in the volume fraction of glass fibres. It can also be seen that the tensile

properties are similar to that expected from randomly orientated E-glass mat

reinforcements of the same fibre volume fraction. This is to be expected as the

architecture of the plain knit has very few straight sections of yarn and certainly none

that are of any significant length. This aspect of the plain knit architecture, as well as

many other standard knit styles, will generally limited the mechanical performance of

knitted composites to values much lower than that expected from conventional 2D

woven fabrics (strengths of E-glass fabrics - 350 - 400 MPa).

Leong et al. (2000) and Anwar et al. (1997), presented tensile results of composites

manufactured from other weft knit architectures (fibre volume fractions of - 53%). Rib

(1x1) specimens had a tensile strength of 96 MPa and a modulus of 14.7 GPa, whilst

full milano architectures gave strength and modulus values of 122 MPa and 14.9 GPa

respectively. Clearly the style of knit architecture is influencing the tensile performance

of the knitted composite. This effect of the knit architecture upon the mechanical

properties of the composite is also observed in the results of Wu et al. (1993) and