Page 217 - 3D Fibre Reinforced Polymer Composites

P. 217

206 30 Fibre Reinforced Polymer Composites

pinned composites is examined based on the limited amount of published data and

information. Included in this chapter is a description of the fabrication techniques, the

in-plane and through-thickness mechanical properties, and impact damage tolerance of

z-pinned composites. 3D sandwich composites manufactured using Z-fiberTM

technology is also briefly described.

9.2 FABRICATION OF Z-PINNED COMPOSITES

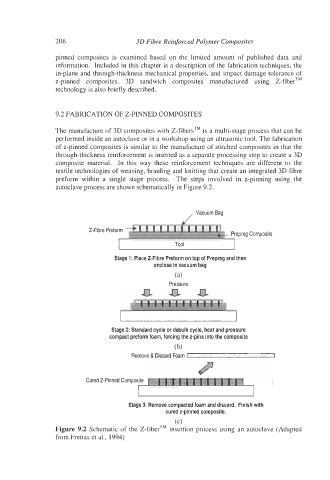

The manufacture of 3D composites with Z-fibersTM is a multi-stage process that can be

performed inside an autoclave or in a workshop using an ultrasonic tool. The fabrication

of z-pinned composites is similar to the manufacture of stitched composites in that the

through-thickness reinforcement is inserted as a separate processing step to create a 3D

composite material. In this way these reinforcement techniques are different to the

textile technologies of weaving, braiding and knitting that create an integrated 3D fibre

preform within a single stage process. The steps involved in z-pinning using the

autoclave process are shown schematically in Figure 9.2.

, VacuumBag

2-Fibre Preform

epreg Composite

Stage 1: Place 2-Fibre Preform on top of Prepreg and then

enclose in vacuum bag

(a)

Pressure

0

Stage 2: Standard cycle or debulk cycle, heat and pressure

compact preform foam, forcing the z-pins into the composite

(b)

Remove & Discard Foam

Cured 2-Pinned Composite

Stage 3: Remove compacted foam and discard. Finish with

cured z-pinned composite.

(c)

Figure 9.2 Schematic of the Z-fiberTM insertion process using an autoclave (Adapted

from Freitas et al., 1994)