Page 218 - 3D Fibre Reinforced Polymer Composites

P. 218

Z-Pinned Composites 207

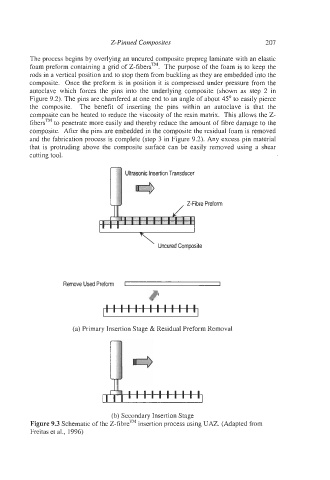

The process begins by overlying an uncured composite prepreg laminate with an elastic

foam preform containing a grid of Z-fibersTM. The purpose of the foam is to keep the

rods in a vertical position and to stop them from buckling as they are embedded into the

composite. Once the preform is in position it is compressed under pressure from the

autoclave which forces the pins into the underlying composite (shown as step 2 in

Figure 9.2). The pins are chamfered at one end to an angle of about 45' to easily pierce

the composite. The benefit of inserting the pins within an autoclave is that the

composite can be heated to reduce the viscosity of the resin matrix. This allows the Z-

fibersTM to penetrate more easily and thereby reduce the amount of fibre damage to the

composite. After the pins are embedded in the composite the residual foam is removed

and the fabrication process is complete (step 3 in Figure 9.2). Any excess pin material

that is protruding above the composite surface can be easily removed using a shear

cutting tool.

Ultrasonic Insertion Transducer

I

, Z-Fibre Preform

\

Uncured Composite

Remove Used Preform

111111111111111

(a) Primary Insertion Stage & Residual Preform Removal

1111111111

11111111111111

(b) Secondary Insertion Stage

Figure 9.3 Schematic of the Z-fibreTM insertion process using UAZ. (Adapted from

Freitas et al., 1996)