Page 44 - 3D Fibre Reinforced Polymer Composites

P. 44

Manufacture of 30 Fibre Preforms 33

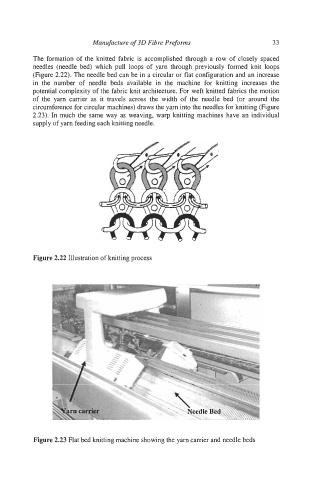

The formation of the knitted fabric is accomplished through a row of closely spaced

needles (needle bed) which pull loops of yarn through previously formed knit loops

(Figure 2.22). The needle bed can be in a circular or flat configuration and an increase

in the number of needle beds available in the machine for knitting increases the

potential complexity of the fabric knit architecture. For weft knitted fabrics the motion

of the yam carrier as it travels across the width of the needle bed (or around the

circumference for circular machines) draws the yarn into the needles for knitting (Figure

2.23). In much the same way as weaving, warp knitting machines have an individual

supply of yarn feeding each knitting needle.

Figure 2.22 Illustration of knitting process

Figure 2.23 Flat bed knitting machine showing the yarn carrier and needle beds