Page 22 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 22

Abbreviations, Terminology and Welding Symbols

. Non-fusible backing bars. These are always removed and

are normally made of copper (often water cooled) or

ceramic and help form the root weld shape. It is important

to ensure that the copper bar does not melt and

contaminate the weld as this could cause weld metal

cracking.

. Fusible backing strips. These are made of a material

similar to the parent material and are tacked on to the

parent material. They are fused into the root and are

normally ground off, or occasionally left in place.

. Pre-placed filler such as EB inserts. These are used on pipe

and welded using a TIG (tungsten inert gas) process. The

EB stands for Electric Boat and is the name of the

company that first supplied them. Use of EB inserts is a

specialised procedure used in specialist applications such

as the nuclear industry.

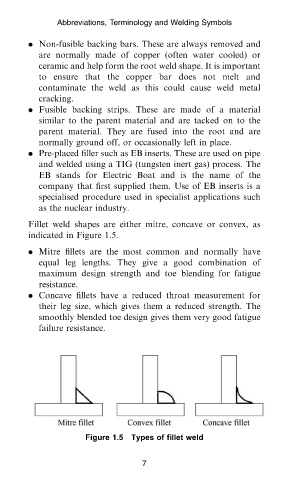

Fillet weld shapes are either mitre, concave or convex, as

indicated in Figure 1.5.

. Mitre fillets are the most common and normally have

equal leg lengths. They give a good combination of

maximum design strength and toe blending for fatigue

resistance.

. Concave fillets have a reduced throat measurement for

their leg size, which gives them a reduced strength. The

smoothly blended toe design gives them very good fatigue

failure resistance.

Figure 1.5 Types of fillet weld

7

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200901QG Welding chap1.3d Page 7 of 16