Page 17 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 17

A Quick Guide to Welding and Weld Inspection

WI: welding inspector

WM: weld metal

WPS: welding procedure specification

Common terms

Longitudinal direction: along the length of the weldment

(parallel to the weld)

Transverse direction: along the width of the weldment

(perpendicular to the weld)

Short transverse direction: through the weldment thickness

Weldment: the combined weld, HAZ and

base metal

Fusion weld: a weld produced by joining

materials in a molten state

Yield point: the point at which plastic

deformation starts in a material

Joint terminology

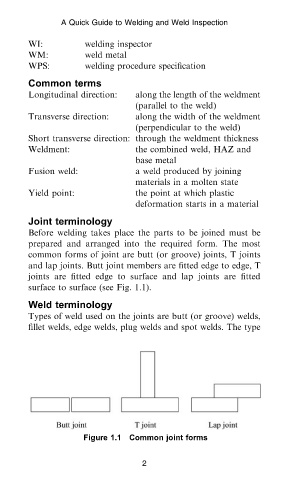

Before welding takes place the parts to be joined must be

prepared and arranged into the required form. The most

common forms of joint are butt (or groove) joints, T joints

and lap joints. Butt joint members are fitted edge to edge, T

joints are fitted edge to surface and lap joints are fitted

surface to surface (see Fig. 1.1).

Weld terminology

Types of weld used on the joints are butt (or groove) welds,

fillet welds, edge welds, plug welds and spot welds. The type

Figure 1.1 Common joint forms

2

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200901QG Welding chap1.3d Page 2 of 16