Page 44 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 44

Analysis of a Fusion Weld

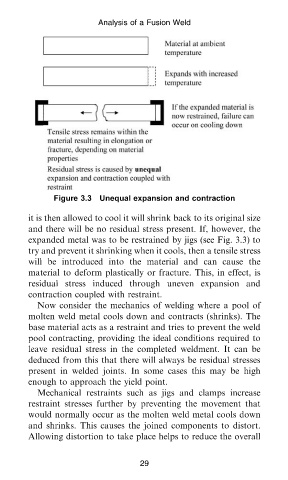

Figure 3.3 Unequal expansion and contraction

it is then allowed to cool it will shrink back to its original size

and there will be no residual stress present. If, however, the

expanded metal was to be restrained by jigs (see Fig. 3.3) to

try and prevent it shrinking when it cools, then a tensile stress

will be introduced into the material and can cause the

material to deform plastically or fracture. This, in effect, is

residual stress induced through uneven expansion and

contraction coupled with restraint.

Now consider the mechanics of welding where a pool of

molten weld metal cools down and contracts (shrinks). The

base material acts as a restraint and tries to prevent the weld

pool contracting, providing the ideal conditions required to

leave residual stress in the completed weldment. It can be

deduced from this that there will always be residual stresses

present in welded joints. In some cases this may be high

enough to approach the yield point.

Mechanical restraints such as jigs and clamps increase

restraint stresses further by preventing the movement that

would normally occur as the molten weld metal cools down

and shrinks. This causes the joined components to distort.

Allowing distortion to take place helps to reduce the overall

29

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200903QG Welding chap3.3d Page 29 of 35