Page 45 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 45

A Quick Guide to Welding and Weld Inspection

stress in the component, but may make the final dimensional

criteria unacceptable with the code requirements. Methods

can be employed that can reduce both residual stress and

distortion (see later).

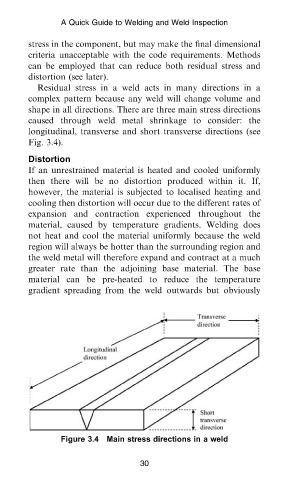

Residual stress in a weld acts in many directions in a

complex pattern because any weld will change volume and

shape in all directions. There are three main stress directions

caused through weld metal shrinkage to consider: the

longitudinal, transverse and short transverse directions (see

Fig. 3.4).

Distortion

If an unrestrained material is heated and cooled uniformly

then there will be no distortion produced within it. If,

however, the material is subjected to localised heating and

cooling then distortion will occur due to the different rates of

expansion and contraction experienced throughout the

material, caused by temperature gradients. Welding does

not heat and cool the material uniformly because the weld

region will always be hotter than the surrounding region and

the weld metal will therefore expand and contract at a much

greater rate than the adjoining base material. The base

material can be pre-heated to reduce the temperature

gradient spreading from the weld outwards but obviously

Figure 3.4 Main stress directions in a weld

30

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200903QG Welding chap3.3d Page 30 of 35