Page 52 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 52

Materials and Their Weldability

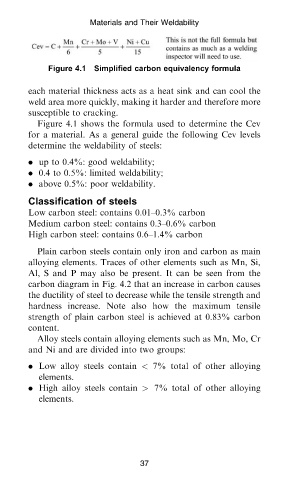

Figure 4.1 Simplified carbon equivalency formula

each material thickness acts as a heat sink and can cool the

weld area more quickly, making it harder and therefore more

susceptible to cracking.

Figure 4.1 shows the formula used to determine the Cev

for a material. As a general guide the following Cev levels

determine the weldability of steels:

. up to 0.4%: good weldability;

. 0.4 to 0.5%: limited weldability;

. above 0.5%: poor weldability.

Classification of steels

Low carbon steel: contains 0.01–0.3% carbon

Medium carbon steel: contains 0.3–0.6% carbon

High carbon steel: contains 0.6–1.4% carbon

Plain carbon steels contain only iron and carbon as main

alloying elements. Traces of other elements such as Mn, Si,

Al, S and P may also be present. It can be seen from the

carbon diagram in Fig. 4.2 that an increase in carbon causes

the ductility of steel to decrease while the tensile strength and

hardness increase. Note also how the maximum tensile

strength of plain carbon steel is achieved at 0.83% carbon

content.

Alloy steels contain alloying elements such as Mn, Mo, Cr

and Ni and are divided into two groups:

. Low alloy steels contain < 7% total of other alloying

elements.

. High alloy steels contain > 7% total of other alloying

elements.

37

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200904QG Welding chap4.3d Page 37 of 48