Page 53 - Quick Guide to Welding and Weld Inspection by S.E. Hughes, Clifford Matthews

P. 53

A Quick Guide to Welding and Weld Inspection

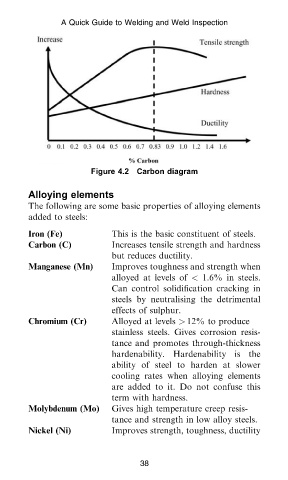

Figure 4.2 Carbon diagram

Alloying elements

The following are some basic properties of alloying elements

added to steels:

Iron (Fe) This is the basic constituent of steels.

Carbon (C) Increases tensile strength and hardness

but reduces ductility.

Manganese (Mn) Improves toughness and strength when

alloyed at levels of < 1.6% in steels.

Can control solidification cracking in

steels by neutralising the detrimental

effects of sulphur.

Chromium (Cr) Alloyed at levels > 12% to produce

stainless steels. Gives corrosion resis-

tance and promotes through-thickness

hardenability. Hardenability is the

ability of steel to harden at slower

cooling rates when alloying elements

are added to it. Do not confuse this

term with hardness.

Molybdenum (Mo) Gives high temperature creep resis-

tance and strength in low alloy steels.

Nickel (Ni) Improves strength, toughness, ductility

38

Woodhead Publishing Ltd – A Quick Guide to Welding and Weld Inspection

Data Standards Ltd, Frome, Somerset – 17/9/200904QG Welding chap4.3d Page 38 of 48