Page 103 - Adsorption Technology & Design, Elsevier (1998)

P. 103

100 Processes and cycles

separated from the fluid by sedimentation, filtration, etc. either for disposal or

for reuse. Powdered activated carbon (PAC) is often used in this way to

remove tastes and odours from waters. If sufficient time is allowed for

equilibrium to be reached then the loading of the adsorbate on the adsorbent

will be related to the final concentration of the adsorbate in the solution via the

thermodynamic isotherm which applies at the final temperature in the process.

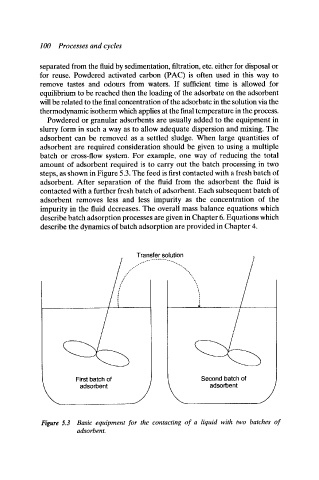

Powdered or granular adsorbents are usually added to the equipment in

slurry form in such a way as to allow adequate dispersion and mixing. The

adsorbent can be removed as a settled sludge. When large quantities of

adsorbent are required consideration should be given to using a multiple

batch or cross-flow system. For example, one way of reducing the total

amount of adsorbent required is to carry out the batch processing in two

steps, as shown in Figure 5.3. The feed is first contacted with a fresh batch of

adsorbent. After separation of the fluid from the adsorbent the fluid is

contacted with a further fresh batch of adsorbent. Each subsequent batch of

adsorbent removes less and less impurity as the concentration of the

impurity in the fluid decreases. The overall mass balance equations which

describe batch adsorption processes are given in Chapter 6. Equations which

describe the dynamics of batch adsorption are provided in Chapter 4.

Transfer olution

s

\

First batch of Second batch of

~k ads~ / ~k~. ads~ /

Figure 5.3 Basic equipment ]'or the contacting of a liquid with two batches of

adsorbent.