Page 187 - Adsorption Technology & Design, Elsevier (1998)

P. 187

Design procedures 173

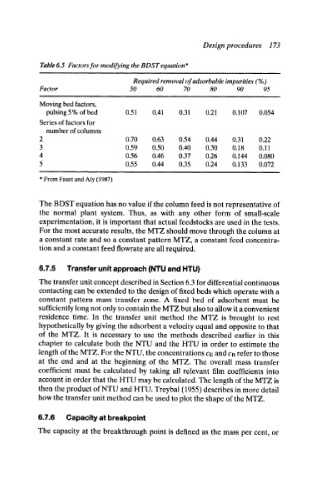

Table 6.5 Factors for modifying the BDST equation*

i i ll|,,

Required removal of adsorbable impurities (%)

Factor 50 60 70 80 90 95

i i i l lll i ill

Moving bed factors,

pulsing 5% of bed 0.51 0.41 0.31 0.21 0.107 0.054

Series of factors for

number of columns

2 0.70 0.63 0.54 0.44 0.31 0.22

3

0.59 0.50 0.40 0.30 0.18 0.11

4

0.56 0.46 0.37 0.26 0.144 0.080

5

0.55 0.44 0.35 0.24 0.133 0.072

,,,,, ,, ,,, , , ,

i ill i i i iii i i i i i

* From Faust and Aly (1987)

The BDST equation has no value if the column feed is not representative of

the normal plant system. Thus, as with any other form of small-scale

experimentation, it is important that actual feedstocks are used in the tests.

For the most accurate results, the MTZ should move through the column at

a constant rate and so a constant pattern MTZ, a constant feed concentra-

tion and a constant feed flowrate are all required.

6.7.5

Transfer unit approach (NTU and HTU)

The transfer unit concept described in Section 6.3 for differential continuous

contacting can be extended to the design of fixed beds which operate with a

constant pattern mass transfer zone. A fixed bed of adsorbent must be

sufficiently long not only to contain the MTZ but also to allow it a convenient

residence time. In the transfer unit method the MTZ is brought to rest

hypothetically by giving the adsorbent a velocity equal and opposite to that

of the MTZ. It is necessary to use the methods described earlier in this

chapter to calculate both the NTU and the HTU in order to estimate the

length of the MTZ. For the NTU, the concentrations cE and ca refer to those

at the end and at the beginning of the MTZ. The overall mass transfer

coefficient must be calculated by taking all relevant film coefficients into

account in order that the HTU may be calculated. The length of the MTZ is

then the product of NTU and HTU. Treybal (1955) describes in more detail

how the transfer unit method can be used to plot the shape of the MTZ.

6.7.6 Capacity at breakpoint

The capacity at the breakthrough point is defined as the mass per cent, or