Page 234 - Adsorption Technology & Design, Elsevier (1998)

P. 234

Selected adsorption processes 213

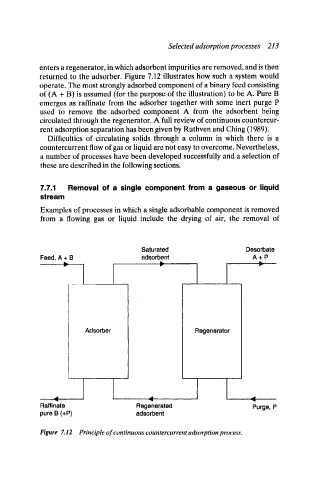

enters a regenerator, in which adsorbent impurities are removed, and is then

returned to the adsorber. Figure 7.12 illustrates how such a system would

operate. The most strongly adsorbed component of a binary feed consisting

of (A + B) is assumed (for the purpose of the illustration) to be A. Pure B

emerges as raffinate from the adsorber together with some inert purge P

used to remove the adsorbed component A from the adsorbent being

circulated through the regenerator. A full review of continuous countercur-

rent adsorption separation has been given by Ruthven and Ching (1989).

Difficulties of circulating solids through a column in which there is a

countercurrent flow of gas or liquid are not easy to overcome. Nevertheless,

a number of processes have been developed successfully and a selection of

these are described in the following sections.

7.7.1 Removal of a single component from a gaseous or liquid

stream

Examples of processes in which a single adsorbable component is removed

from a flowing gas or liquid include the drying of air, the removal of

Saturated Desorbate

Feed, A + B adsorbent A + P

' i v ~- ~ " . . . . . . . . . . IF" ' I =F '"

Adsorber Regenerator

..... ~ ~ ....... ~ . . . . . . .

Raffinate Regenerated Purge, P

pure B (+P) adsorbent

Figure 7.12 Principle of continuous countercurrent adsorption process.