Page 235 - Adsorption Technology & Design, Elsevier (1998)

P. 235

214 Selected adsorption processes

vaporized organic solvents from air, the removal of organic compounds

from waste water streams, ion exchange processes and sugar decolouriza-

tion. Although the principle inherent in all of these processes is the

adsorption, and hence removal, of an undesirable component from a

process fluid which itself is not adsorbed, the mode of operation varies from

one process to another. For example, the regeneration of the adsorbent may

be by means of heat application or by a purge at a temperature close to that

at which the adsorption occurs. In solvent recovery processes, steam

stripping is a common procedure for regeneration. The mode of solids

conveying also varies from one process to another. The Union Carbide

Purasiv process for the recovery of organic solvents from gaseous streams

(Keller 1983) is illustrated in Figure 5.9.

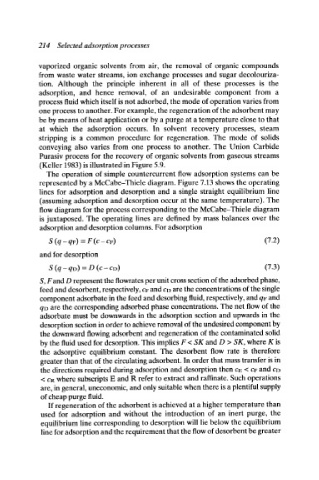

The operation of simple countercurrent flow adsorption systems can be

represented by a McCabe-Thiele diagram. Figure 7.13 shows the operating

lines for adsorption and desorption and a single straight equilibrium line

(assuming adsorption and desorption occur at the same temperature). The

flow diagram for the process corresponding to the McCabe-Thiele diagram

is juxtaposed. The operating lines are defined by mass balances over the

adsorption and desorption columns. For adsorption

(7.2)

S (q - qF) = F (c - CF)

and for desorption

(7.3)

S (q- qD) = D (c-CD)

S, F and D represent the flowrates per unit cross section of the adsorbed phase,

feed and desorbent, respectively, cr and co are the concentrations of the single

component adsorbate in the feed and desorbing fluid, respectively, and qF and

qD are the corresponding adsorbed phase concentrations. The net flow of the

adsorbate must be downwards in the adsorption section and upwards in the

desorption section in order to achieve removal of the undesired component by

the downward flowing adsorbent and regeneration of the contaminated solid

by the fluid used for desorption. This implies F < SK and D > SK, where K is

the adsorptive equilibrium constant. The desorbent flow rate is therefore

greater than that of the circulating adsorbent. In order that mass transfer is in

the directions required during adsorption and desorption then CE < CF and co

< CR where subscripts E and R refer to extract and raffinate. Such operations

are, in general, uneconomic, and only suitable when there is a plentiful supply

of cheap purge fluid.

If regeneration of the adsorbent is achieved at a higher temperature than

used for adsorption and without the introduction of an inert purge, the

equilibrium line corresponding to desorption will lie below the equilibrium

line for adsorption and the requirement that the flow of desorbent be greater