Page 52 - Adsorption, Ion Exchange & Catalysis- 2007, Elsevier - Copy

P. 52

Else_AIEC-INGLE_cH002.qxd 6/20/2006 11:32 AM Page 48

48 2. Adsorption, Ion Exchange, and Catalysis

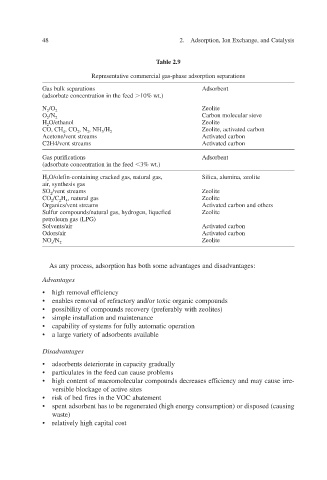

Table 2.9

Representative commercial gas-phase adsorption separations

Gas bulk separations Adsorbent

(adsorbate concentration in the feed 10% wt.)

N 2 /O 2 Zeolite

O 2 /N 2 e v Carbon molecular sie

H 2 O/ethanol Zeolite

CO, CH 4 ,C O 2 ,N 2 ,N H 3 /H 2 Zeolite, acti ated carbon v

Acetone/vent streams Activated carbon

C2H4/vent streams Activated carbon

ications Gas purif Adsorbent

(adsorbate concentration in the feed 3% wt.)

H 2 O/olefin-containing cracked gas, natural gas, Silica, alumina, zeolite

air, synthesis gas

SO 2 /vent streams Zeolite

CO 2 /C 2 H 4 , natural gas Zeolite

Organics/vent streams Activated carbon and others

Sulfur compounds/natural gas, hydrogen, liquef ied Zeolite

petroleum gas (LPG)

Solvents/air Activated carbon

Odors/air Activated carbon

NO x /N 2 Zeolite

As any process, adsorption has both some advantages and disadv antages:

age Advants

• v high remoal efficiency

• enables remoal of refractory and/or toxic organic compounds v

• possibility of compounds recoery (preferably with zeolites) v

• simple installation and maintenance

• capability of systems for fully automatic operation

• a large variety of adsorbents a ailable v

Disadvantages

• adsorbents deteriorate in capacity gradually

• particulates in the feed can cause problems

• high content of macromolecular compounds decreases efy and may cause irre- f icienc

versible blockage of acti e sites v

• risk of bed fires in the OC abatement V

• spent adsorbent has to be regenerated (high energy consumption) or disposed (causing

waste)

• relatively high capital cost