Page 163 - Advanced Mine Ventilation

P. 163

Respirable Dust Control 143

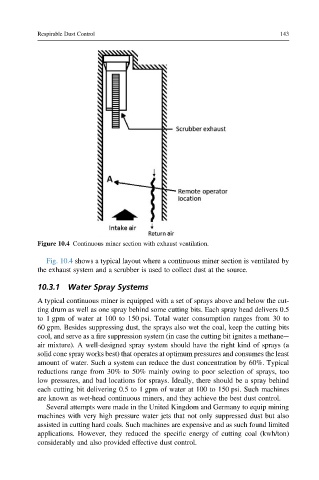

Figure 10.4 Continuous miner section with exhaust ventilation.

Fig. 10.4 shows a typical layout where a continuous miner section is ventilated by

the exhaust system and a scrubber is used to collect dust at the source.

10.3.1 Water Spray Systems

A typical continuous miner is equipped with a set of sprays above and below the cut-

ting drum as well as one spray behind some cutting bits. Each spray head delivers 0.5

to 1 gpm of water at 100 to 150 psi. Total water consumption ranges from 30 to

60 gpm. Besides suppressing dust, the sprays also wet the coal, keep the cutting bits

cool, and serve as a fire suppression system (in case the cutting bit ignites a methanee

air mixture). A well-designed spray system should have the right kind of sprays (a

solid cone spray works best) that operates at optimum pressures and consumes the least

amount of water. Such a system can reduce the dust concentration by 60%. Typical

reductions range from 30% to 50% mainly owing to poor selection of sprays, too

low pressures, and bad locations for sprays. Ideally, there should be a spray behind

each cutting bit delivering 0.5 to 1 gpm of water at 100 to 150 psi. Such machines

are known as wet-head continuous miners, and they achieve the best dust control.

Several attempts were made in the United Kingdom and Germany to equip mining

machines with very high pressure water jets that not only suppressed dust but also

assisted in cutting hard coals. Such machines are expensive and as such found limited

applications. However, they reduced the specific energy of cutting coal (kwh/ton)

considerably and also provided effective dust control.