Page 164 - Advanced Mine Ventilation

P. 164

144 Advanced Mine Ventilation

10.3.2 Water Scrubbers

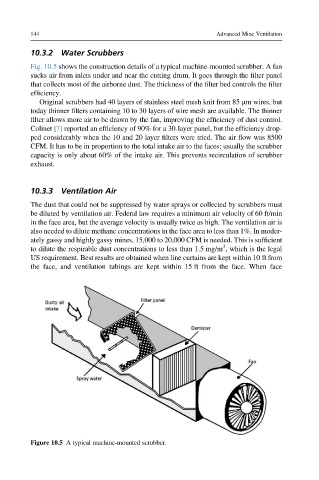

Fig. 10.5 shows the construction details of a typical machine-mounted scrubber. A fan

sucks air from inlets under and near the cutting drum. It goes through the filter panel

that collects most of the airborne dust. The thickness of the filter bed controls the filter

efficiency.

Original scrubbers had 40 layers of stainless steel mesh knit from 85 mm wires, but

today thinner filters containing 10 to 30 layers of wire mesh are available. The thinner

filter allows more air to be drawn by the fan, improving the efficiency of dust control.

Colinet [7] reported an efficiency of 90% for a 30-layer panel, but the efficiency drop-

ped considerably when the 10 and 20 layer filters were tried. The air flow was 8500

CFM. It has to be in proportion to the total intake air to the faces; usually the scrubber

capacity is only about 60% of the intake air. This prevents recirculation of scrubber

exhaust.

10.3.3 Ventilation Air

The dust that could not be suppressed by water sprays or collected by scrubbers must

be diluted by ventilation air. Federal law requires a minimum air velocity of 60 ft/min

in the face area, but the average velocity is usually twice as high. The ventilation air is

also needed to dilute methane concentrations in the face area to less than 1%. In moder-

ately gassy and highly gassy mines, 15,000 to 20,000 CFM is needed. This is sufficient

3

to dilute the respirable dust concentrations to less than 1.5 mg/m , which is the legal

US requirement. Best results are obtained when line curtains are kept within 10 ft from

the face, and ventilation tubings are kept within 15 ft from the face. When face

Figure 10.5 A typical machine-mounted scrubber.