Page 169 - Advanced Mine Ventilation

P. 169

Respirable Dust Control 149

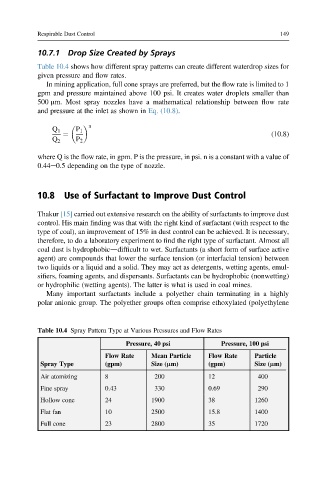

10.7.1 Drop Size Created by Sprays

Table 10.4 shows how different spray patterns can create different waterdrop sizes for

given pressure and flow rates.

In mining application, full cone sprays are preferred, but the flow rate is limited to 1

gpm and pressure maintained above 100 psi. It creates water droplets smaller than

500 mm. Most spray nozzles have a mathematical relationship between flow rate

and pressure at the inlet as shown in Eq. (10.8).

Q 1 n

P 1

¼ (10.8)

Q 2 P 2

where Q is the flow rate, in gpm. P is the pressure, in psi. n is a constant with a value of

0.44e0.5 depending on the type of nozzle.

10.8 Use of Surfactant to Improve Dust Control

Thakur [15] carried out extensive research on the ability of surfactants to improve dust

control. His main finding was that with the right kind of surfactant (with respect to the

type of coal), an improvement of 15% in dust control can be achieved. It is necessary,

therefore, to do a laboratory experiment to find the right type of surfactant. Almost all

coal dust is hydrophobicddifficult to wet. Surfactants (a short form of surface active

agent) are compounds that lower the surface tension (or interfacial tension) between

two liquids or a liquid and a solid. They may act as detergents, wetting agents, emul-

sifiers, foaming agents, and dispersants. Surfactants can be hydrophobic (nonwetting)

or hydrophilic (wetting agents). The latter is what is used in coal mines.

Many important surfactants include a polyether chain terminating in a highly

polar anionic group. The polyether groups often comprise ethoxylated (polyethylene

Table 10.4 Spray Pattern Type at Various Pressures and Flow Rates

Pressure, 40 psi Pressure, 100 psi

Flow Rate Mean Particle Flow Rate Particle

Spray Type (gpm) Size (mm) (gpm) Size (mm)

Air atomizing 8 200 12 400

Fine spray 0.43 330 0.69 290

Hollow cone 24 1900 38 1260

Flat fan 10 2500 15.8 1400

Full cone 23 2800 35 1720