Page 184 - Advanced Mine Ventilation

P. 184

164 Advanced Mine Ventilation

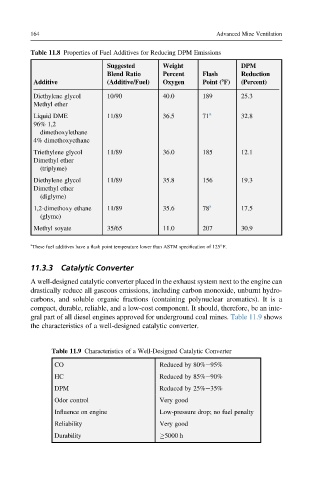

Table 11.8 Properties of Fuel Additives for Reducing DPM Emissions

Suggested Weight DPM

Blend Ratio Percent Flash Reduction

Additive (Additive/Fuel) Oxygen Point (8F) (Percent)

Diethylene glycol 10/90 40.0 189 25.3

Methyl ether

Liquid DME 11/89 36.5 71 a 32.8

96% 1,2

dimethoxylethane

4% dimethoxyethane

Triethylene glycol 11/89 36.0 185 12.1

Dimethyl ether

(triplyme)

Diethylene glycol 11/89 35.8 156 19.3

Dimethyl ether

(diglyme)

1,2-dimethoxy ethane 11/89 35.6 78 a 17.5

(glyme)

Methyl soyate 35/65 11.0 207 30.9

a

These fuel additives have a flash point temperature lower than ASTM specification of 125 F.

11.3.3 Catalytic Converter

A well-designed catalytic converter placed in the exhaust system next to the engine can

drastically reduce all gaseous emissions, including carbon monoxide, unburnt hydro-

carbons, and soluble organic fractions (containing polynuclear aromatics). It is a

compact, durable, reliable, and a low-cost component. It should, therefore, be an inte-

gral part of all diesel engines approved for underground coal mines. Table 11.9 shows

the characteristics of a well-designed catalytic converter.

Table 11.9 Characteristics of a Well-Designed Catalytic Converter

CO Reduced by 80%e95%

HC Reduced by 85%e90%

DPM Reduced by 25%e35%

Odor control Very good

Influence on engine Low-pressure drop; no fuel penalty

Reliability Very good

Durability 5000 h