Page 182 - Advanced Mine Ventilation

P. 182

162 Advanced Mine Ventilation

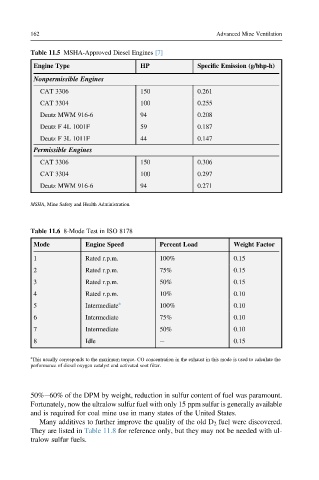

Table 11.5 MSHA-Approved Diesel Engines [7]

Engine Type HP Specific Emission (g/bhp-h)

Nonpermissible Engines

CAT 3306 150 0.261

CAT 3304 100 0.255

Deutz MWM 916-6 94 0.208

Deutz F 4L 1001F 59 0.187

Deutz F 3L 1011F 44 0.147

Permissible Engines

CAT 3306 150 0.306

CAT 3304 100 0.297

Deutz MWM 916-6 94 0.271

MSHA, Mine Safety and Health Administration.

Table 11.6 8-Mode Test in ISO 8178

Mode Engine Speed Percent Load Weight Factor

1 Rated r.p.m. 100% 0.15

2 Rated r.p.m. 75% 0.15

3 Rated r.p.m. 50% 0.15

4 Rated r.p.m. 10% 0.10

5 Intermediate a 100% 0.10

6 Intermediate 75% 0.10

7 Intermediate 50% 0.10

8 Idle e 0.15

a

This usually corresponds to the maximum torque. CO concentration in the exhaust in this mode is used to calculate the

performance of diesel oxygen catalyst and activated soot filter.

50%e60% of the DPM by weight, reduction in sulfur content of fuel was paramount.

Fortunately, now the ultralow sulfur fuel with only 15 ppm sulfur is generally available

and is required for coal mine use in many states of the United States.

Many additives to further improve the quality of the old D 2 fuel were discovered.

They are listed in Table 11.8 for reference only, but they may not be needed with ul-

tralow sulfur fuels.