Page 178 - Advanced Mine Ventilation

P. 178

158 Advanced Mine Ventilation

6. Belts for coal transport versus mine cars and locomotives.

7. Mine slopes versus vertical hoists.

8. Trained and skilled personnel versus on-the-job training.

9. Zero accident goals versus fewer accidents than the previous year.

The use of diesel equipment in coal mines in the past was questioned based on the

suspicion that exposure to diesel exhaust may affect the health of miners. Diesel en-

gines were introduced in US underground coal mines nearly 50 years ago, and their

numbers have steadily increased to approximately 5000 at present. Safety and produc-

tivity advantages are the driving forces for the popularity of diesel engines. Diesel

equipment improves safety by eliminating shock, fire, and explosion hazards from trol-

ley wires and electrical cable equipment.

An additional safety advantage of diesel equipment use is improved ventilation in

the face area. Currently, the belt entry is isolated from intake air in many mines, and the

trolley wire entry is regulated for air velocity at 250 ft per minute. The latter restriction

is imposed to safeguard against rapid spreading of fire in the trolley wire entry, but all

such restrictions can be eliminated with the use of diesel equipment, and air quantities

at the face can be maximized to improve safety and health of miners.

11.1 Health Hazards of Diesel Particulate Matter

Diesel exhaust contains some substances that can be potentially harmful to human

health at high exposure levels. However, the toxicological effects of any substance

are functions of the dose and duration of exposure. For example, carbon monoxide

is a deadly substance in very high concentrations. The American Conference of

Governmental Industrial Hygienists (ACGIH) has set a threshold limit value for it at

50 ppm. This means it can be inhaled at this concentration for 8 h a day, 5 days a

week over the lifetime of a worker without harmful effects. Similarly, if all compo-

nents of the diesel exhaust are diluted to their respective threshold limit values

(TLVs), diesel exhaust does not constitute a hazard to human health.

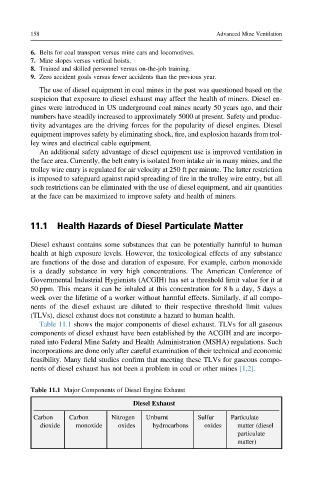

Table 11.1 shows the major components of diesel exhaust. TLVs for all gaseous

components of diesel exhaust have been established by the ACGIH and are incorpo-

rated into Federal Mine Safety and Health Administration (MSHA) regulations. Such

incorporations are done only after careful examination of their technical and economic

feasibility. Many field studies confirm that meeting these TLVs for gaseous compo-

nents of diesel exhaust has not been a problem in coal or other mines [1,2].

Table 11.1 Major Components of Diesel Engine Exhaust

Diesel Exhaust

Carbon Carbon Nitrogen Unburnt Sulfur Particulate

dioxide monoxide oxides hydrocarbons oxides matter (diesel

particulate

matter)