Page 211 - Advanced Mine Ventilation

P. 211

Respirable Dust Sampling and Measurement 191

to three fields were counted to get an average. An average count of 50 per field was

equal to:

6

58:8 10 particles per cubic foot ¼ 2; 079 pp cc.

The instrument suffered from the same defects as the Konimeter and was eventually

abandoned.

12.1.3 Thermal Precipitator

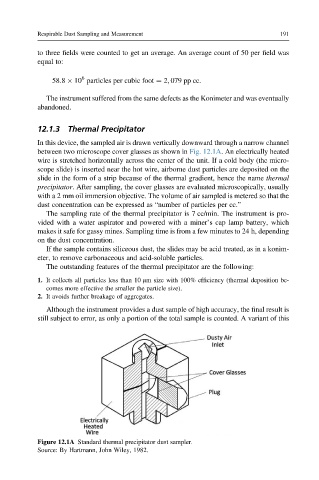

In this device, the sampled air is drawn vertically downward through a narrow channel

between two microscope cover glasses as shown in Fig. 12.1A. An electrically heated

wire is stretched horizontally across the center of the unit. If a cold body (the micro-

scope slide) is inserted near the hot wire, airborne dust particles are deposited on the

slide in the form of a strip because of the thermal gradient, hence the name thermal

precipitator. After sampling, the cover glasses are evaluated microscopically, usually

with a 2 mm oil immersion objective. The volume of air sampled is metered so that the

dust concentration can be expressed as “number of particles per cc.”

The sampling rate of the thermal precipitator is 7 cc/min. The instrument is pro-

vided with a water aspirator and powered with a miner’s cap lamp battery, which

makes it safe for gassy mines. Sampling time is from a few minutes to 24 h, depending

on the dust concentration.

If the sample contains siliceous dust, the slides may be acid treated, as in a konim-

eter, to remove carbonaceous and acid-soluble particles.

The outstanding features of the thermal precipitator are the following:

1. It collects all particles less than 10 mm size with 100% efficiency (thermal deposition be-

comes more effective the smaller the particle size).

2. It avoids further breakage of aggregates.

Although the instrument provides a dust sample of high accuracy, the final result is

still subject to error, as only a portion of the total sample is counted. A variant of this

Figure 12.1A Standard thermal precipitator dust sampler.

Source: By Hartmann, John Wiley, 1982.