Page 265 - Advanced Mine Ventilation

P. 265

242 Advanced Mine Ventilation

Table 14.3 Sorption Time and Diffusivity for Some US Coal Seams

L1

Coal Seam Sorption Time (days) (D/a 2 )(s )

Pittsburgh 100e900 4.0 10 9 to 4.4 10 10

Pocahontas #3 1e3 4.0 10 7 to 1.34 10 7

Mary Lee/Blue Creek 3e5 1.34 10 7 to 8.0 10 8

San Juan Basin 1 4.0 10 7

14.4 Reservoir Pressure

All coal seams have a gas pressure that keeps methane adsorbed in coal. This is called

“reservoir or pore pressure.” For design of degasification and assessment of the effect

of degasification, it is essential to know it in advance of mining. It is primarily a factor

of the depth of burial and the rank of coal. The greater the depth of the coal seam and

the higher the rank of coal, the higher the pore pressure. However, there are a few

exceptions.

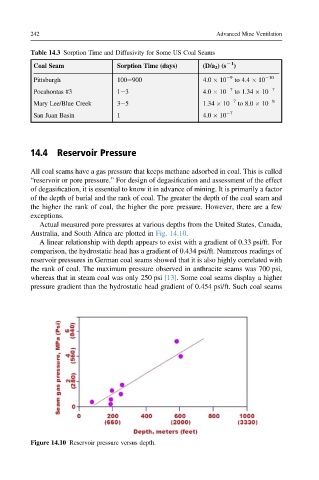

Actual measured pore pressures at various depths from the United States, Canada,

Australia, and South Africa are plotted in Fig. 14.10.

A linear relationship with depth appears to exist with a gradient of 0.33 psi/ft. For

comparison, the hydrostatic head has a gradient of 0.434 psi/ft. Numerous readings of

reservoir pressures in German coal seams showed that it is also highly correlated with

the rank of coal. The maximum pressure observed in anthracite seams was 700 psi,

whereas that in steam coal was only 250 psi [13]. Some coal seams display a higher

pressure gradient than the hydrostatic head gradient of 0.454 psi/ft. Such coal seams

Figure 14.10 Reservoir pressure versus depth.