Page 276 - Advanced Mine Ventilation

P. 276

Premining Degasification of Coal Seams 253

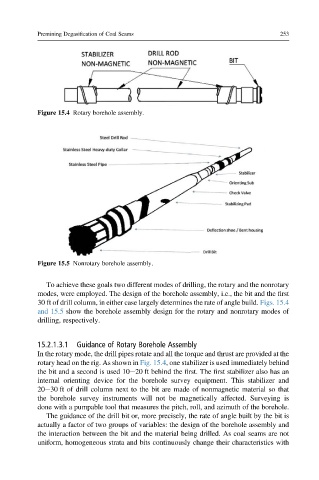

Figure 15.4 Rotary borehole assembly.

Figure 15.5 Nonrotary borehole assembly.

To achieve these goals two different modes of drilling, the rotary and the nonrotary

modes, were employed. The design of the borehole assembly, i.e., the bit and the first

30 ft of drill column, in either case largely determines the rate of angle build. Figs. 15.4

and 15.5 show the borehole assembly design for the rotary and nonrotary modes of

drilling, respectively.

15.2.1.3.1 Guidance of Rotary Borehole Assembly

In the rotary mode, the drill pipes rotate and all the torque and thrust are provided at the

rotary head on the rig. As shown in Fig. 15.4, one stabilizer is used immediately behind

the bit and a second is used 10e20 ft behind the first. The first stabilizer also has an

internal orienting device for the borehole survey equipment. This stabilizer and

20e30 ft of drill column next to the bit are made of nonmagnetic material so that

the borehole survey instruments will not be magnetically affected. Surveying is

done with a pumpable tool that measures the pitch, roll, and azimuth of the borehole.

The guidance of the drill bit or, more precisely, the rate of angle built by the bit is

actually a factor of two groups of variables: the design of the borehole assembly and

the interaction between the bit and the material being drilled. As coal seams are not

uniform, homogeneous strata and bits continuously change their characteristics with