Page 324 - Advanced Mine Ventilation

P. 324

Gas Transport in Underground Coal Mines 301

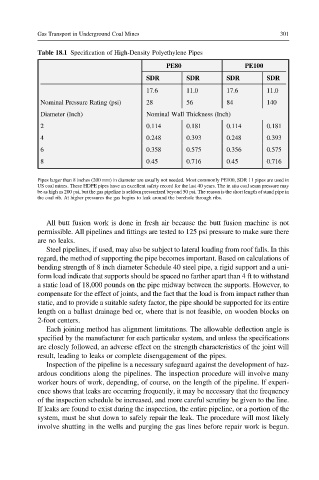

Table 18.1 Specification of High-Density Polyethylene Pipes

PE80 PE100

SDR SDR SDR SDR

17.6 11.0 17.6 11.0

Nominal Pressure Rating (psi) 28 56 84 140

Diameter (Inch) Nominal Wall Thickness (Inch)

2 0.114 0.181 0.114 0.181

4 0.248 0.393 0.248 0.393

6 0.358 0.575 0.356 0.575

8 0.45 0.716 0.45 0.716

Pipes larger than 8 inches (200 mm) in diameter are usually not needed. Most commonly PE100, SDR 11 pipes are used in

US coal mines. These HDPE pipes have an excellent safety record for the last 40 years. The in situ coal seam pressure may

be as high as 200 psi, but the gas pipeline is seldom pressurized beyond 50 psi. The reason is the short length of stand pipe in

the coal rib. At higher pressures the gas begins to leak around the borehole through ribs.

All butt fusion work is done in fresh air because the butt fusion machine is not

permissible. All pipelines and fittings are tested to 125 psi pressure to make sure there

are no leaks.

Steel pipelines, if used, may also be subject to lateral loading from roof falls. In this

regard, the method of supporting the pipe becomes important. Based on calculations of

bending strength of 8 inch diameter Schedule 40 steel pipe, a rigid support and a uni-

form load indicate that supports should be spaced no farther apart than 4 ft to withstand

a static load of 18,000 pounds on the pipe midway between the supports. However, to

compensate for the effect of joints, and the fact that the load is from impact rather than

static, and to provide a suitable safety factor, the pipe should be supported for its entire

length on a ballast drainage bed or, where that is not feasible, on wooden blocks on

2-foot centers.

Each joining method has alignment limitations. The allowable deflection angle is

specified by the manufacturer for each particular system, and unless the specifications

are closely followed, an adverse effect on the strength characteristics of the joint will

result, leading to leaks or complete disengagement of the pipes.

Inspection of the pipeline is a necessary safeguard against the development of haz-

ardous conditions along the pipelines. The inspection procedure will involve many

worker hours of work, depending, of course, on the length of the pipeline. If experi-

ence shows that leaks are occurring frequently, it may be necessary that the frequency

of the inspection schedule be increased, and more careful scrutiny be given to the line.

If leaks are found to exist during the inspection, the entire pipeline, or a portion of the

system, must be shut down to safely repair the leak. The procedure will most likely

involve shutting in the wells and purging the gas lines before repair work is begun.