Page 73 - Advanced Mine Ventilation

P. 73

56 Advanced Mine Ventilation

1.2

0.9

Spacing

Width

0.6

0.5

0.3

400 600 700 800 1000 1200

Width of Longwall Face, ft.

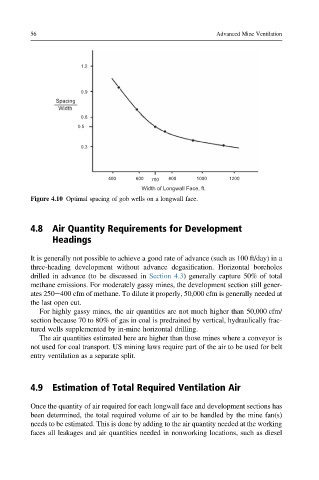

Figure 4.10 Optimal spacing of gob wells on a longwall face.

4.8 Air Quantity Requirements for Development

Headings

It is generally not possible to achieve a good rate of advance (such as 100 ft/day) in a

three-heading development without advance degasification. Horizontal boreholes

drilled in advance (to be discussed in Section 4.3) generally capture 50% of total

methane emissions. For moderately gassy mines, the development section still gener-

ates 250e400 cfm of methane. To dilute it properly, 50,000 cfm is generally needed at

the last open cut.

For highly gassy mines, the air quantities are not much higher than 50,000 cfm/

section because 70 to 80% of gas in coal is predrained by vertical, hydraulically frac-

tured wells supplemented by in-mine horizontal drilling.

The air quantities estimated here are higher than those mines where a conveyor is

not used for coal transport. US mining laws require part of the air to be used for belt

entry ventilation as a separate split.

4.9 Estimation of Total Required Ventilation Air

Once the quantity of air required for each longwall face and development sections has

been determined, the total required volume of air to be handled by the mine fan(s)

needs to be estimated. This is done by adding to the air quantity needed at the working

faces all leakages and air quantities needed in nonworking locations, such as diesel