Page 270 - Advances In Productive, Safe, and Responsible Coal Mining

P. 270

Sustainable coal waste disposal practices 249

Water supply well

Runoff (Make-up water)

Fresh water (optional)

impoundment

Wash plant supply water

Runoff Coarse coal refuse embankment

ROM

coal Coal Coal slurry

preparation

impoundment

(wash) plant

Runoff or dewatered

Clean FCPW fill

coal

Sedimentation Coal stockpiles

impoundment

Thickener

Mine water

supply well

(dust control)

Mine

dewatering Slurry

well dewatering

Alternative slurry facility

processing strategies

Slurry impoundment decant water and runoff

NPDES discharge (periodic blowdown)—Possible discharge to a mixing zone

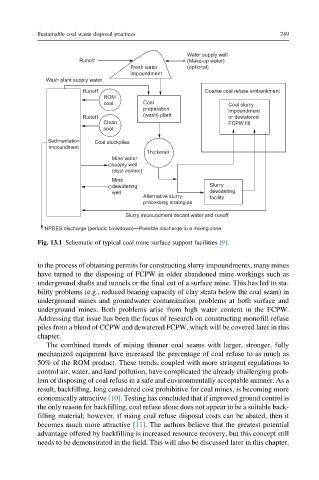

Fig. 13.1 Schematic of typical coal mine surface support facilities [9].

to the process of obtaining permits for constructing slurry impoundments, many mines

have turned to the disposing of FCPW in older abandoned mine workings such as

underground shafts and tunnels or the final cut of a surface mine. This has led to sta-

bility problems (e.g., reduced bearing capacity of clay strata below the coal seam) in

underground mines and groundwater contamination problems at both surface and

underground mines. Both problems arise from high water content in the FCPW.

Addressing that issue has been the focus of research on constructing monofill refuse

piles from a blend of CCPW and dewatered FCPW, which will be covered later in this

chapter.

The combined trends of mining thinner coal seams with larger, stronger, fully

mechanized equipment have increased the percentage of coal refuse to as much as

50% of the ROM product. These trends, coupled with more stringent regulations to

control air, water, and land pollution, have complicated the already challenging prob-

lem of disposing of coal refuse in a safe and environmentally acceptable manner. As a

result, backfilling, long considered cost prohibitive for coal mines, is becoming more

economically attractive [10]. Testing has concluded that if improved ground control is

the only reason for backfilling, coal refuse alone does not appear to be a suitable back-

filling material; however, if rising coal refuse disposal costs can be abated, then it

becomes much more attractive [11]. The authors believe that the greatest potential

advantage offered by backfilling is increased resource recovery, but this concept still

needs to be demonstrated in the field. This will also be discussed later in this chapter.