Page 168 - Advances in Eco-Fuels for a Sustainable Environment

P. 168

Microwave-assisted fast pyrolysis of hazardous waste engine oil into green fuels 139

Electrical pyrolysis with stirrer speed 10 rpm Electrical pyrolysis with stirrer speed 20 rpm

5.0 5.0

4.5 4.5

Nitrogen flow rate (L/min) 3.5 Nitrogen flow rate (L/min) 3.5

4.0

4.0

3.0

3.0

2.5 2.5

2.0 08% 2.0

260 280 300 320 340 10% 260 280 300 320 340

Temperature (°C) 12% Temperature (°C)

14%

16%

Microwave pyrolysis with stirrer speed 10 rpm 18% Microwave pyrolysis with stirrer speed 20 rpm

5.0 20% 5.0

22%

24%

4.5 4.5

Nitrogen flow rate (L/min) 4.0 Nitrogen flow rate (L/min) 4.0

3.5

3.5

3.0

3.0

2.5 2.5

2.0 2.0

300 320 340 360 380 400 300 320 340 360 380 400

Temperature (°C) Temperature (°C)

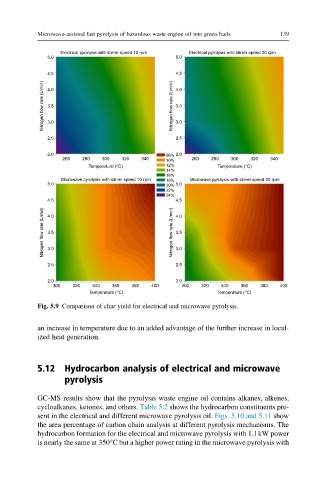

Fig. 5.9 Comparison of char yield for electrical and microwave pyrolysis.

an increase in temperature due to an added advantage of the further increase in local-

ized heat generation.

5.12 Hydrocarbon analysis of electrical and microwave

pyrolysis

GC-MS results show that the pyrolysis waste engine oil contains alkanes, alkenes,

cycloalkanes, ketones, and others. Table 5.2 shows the hydrocarbon constituents pre-

sent in the electrical and different microwave pyrolysis oil. Figs. 5.10 and 5.11 show

the area percentage of carbon chain analysis at different pyrolysis mechanisms. The

hydrocarbon formation for the electrical and microwave pyrolysis with 1.1kW power

is nearly the same at 350°C but a higher power rating in the microwave pyrolysis with