Page 164 - Advances in Eco-Fuels for a Sustainable Environment

P. 164

Microwave-assisted fast pyrolysis of hazardous waste engine oil into green fuels 135

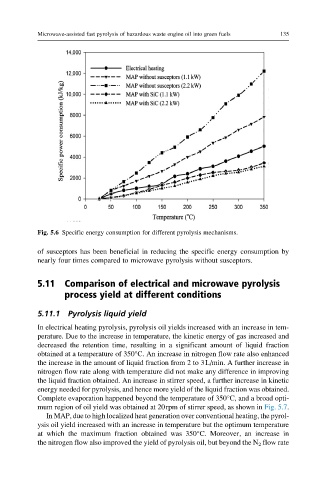

Fig. 5.6 Specific energy consumption for different pyrolysis mechanisms.

of susceptors has been beneficial in reducing the specific energy consumption by

nearly four times compared to microwave pyrolysis without susceptors.

5.11 Comparison of electrical and microwave pyrolysis

process yield at different conditions

5.11.1 Pyrolysis liquid yield

In electrical heating pyrolysis, pyrolysis oil yields increased with an increase in tem-

perature. Due to the increase in temperature, the kinetic energy of gas increased and

decreased the retention time, resulting in a significant amount of liquid fraction

obtained at a temperature of 350°C. An increase in nitrogen flow rate also enhanced

the increase in the amount of liquid fraction from 2 to 3L/min. A further increase in

nitrogen flow rate along with temperature did not make any difference in improving

the liquid fraction obtained. An increase in stirrer speed, a further increase in kinetic

energy needed for pyrolysis, and hence more yield of the liquid fraction was obtained.

Complete evaporation happened beyond the temperature of 350°C, and a broad opti-

mum region of oil yield was obtained at 20rpm of stirrer speed, as shown in Fig. 5.7.

In MAP, due to high localized heat generation over conventional heating, the pyrol-

ysis oil yield increased with an increase in temperature but the optimum temperature

at which the maximum fraction obtained was 350°C. Moreover, an increase in

the nitrogen flow also improved the yield of pyrolysis oil, but beyond the N 2 flow rate