Page 162 - Advances in Eco-Fuels for a Sustainable Environment

P. 162

Microwave-assisted fast pyrolysis of hazardous waste engine oil into green fuels 133

TG (%) DSC (mW/mg)

exo

Value: 154.6°C, 99.7% Peak: 344.3°C, 2.156 mW/mg

100

2.0

80 1.5

Value: 344.5°C, 51.2% 1.0

60

0.5

40

Value: 457.0°C, –0.8661 mW/mg

0.0

20 –0.5

Value: 67.2°C, –0.4928 mW/mg

[1]

[1]

–1.0

0 Residual mass: 4.4% (597.7°C)

100 200 300 400 500

PWEO Temperature (°C)

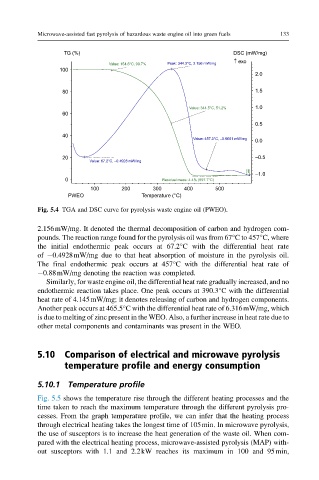

Fig. 5.4 TGA and DSC curve for pyrolysis waste engine oil (PWEO).

2.156mW/mg. It denoted the thermal decomposition of carbon and hydrogen com-

pounds. The reaction range found for the pyrolysis oil was from 67°C to 457°C, where

the initial endothermic peak occurs at 67.2°C with the differential heat rate

of 0.4928mW/mg due to that heat absorption of moisture in the pyrolysis oil.

The final endothermic peak occurs at 457°C with the differential heat rate of

0.88mW/mg denoting the reaction was completed.

Similarly, for waste engine oil, the differential heat rate gradually increased, and no

endothermic reaction takes place. One peak occurs at 390.3°C with the differential

heat rate of 4.145mW/mg; it denotes releasing of carbon and hydrogen components.

Another peak occurs at 465.5°C with the differential heat rate of 6.316mW/mg, which

is due to melting of zinc present in the WEO. Also, a further increase in heat rate due to

other metal components and contaminants was present in the WEO.

5.10 Comparison of electrical and microwave pyrolysis

temperature profile and energy consumption

5.10.1 Temperature profile

Fig. 5.5 shows the temperature rise through the different heating processes and the

time taken to reach the maximum temperature through the different pyrolysis pro-

cesses. From the graph temperature profile, we can infer that the heating process

through electrical heating takes the longest time of 105min. In microwave pyrolysis,

the use of susceptors is to increase the heat generation of the waste oil. When com-

pared with the electrical heating process, microwave-assisted pyrolysis (MAP) with-

out susceptors with 1.1 and 2.2kW reaches its maximum in 100 and 95min,