Page 211 - Advances in Eco-Fuels for a Sustainable Environment

P. 211

Anaerobic digestion of various feedstocks for second-generation biofuel production 175

Methane

Conventional catalytic Homogeneous radical gas

processing

processes phase reaction

method:

oxidation

process Plasma technologies

Low temperature

homogeneous catalyst

Photo-catalytic

Conversions technologies

technologies Homogeneous catalyst in

solution

Supercritical water

oxidation technologies

Bio catalyst based on

Membrane enzymes

Yielding

technologies

production:

methanol Fuel cell

Other

technologies

Electro-synthesis

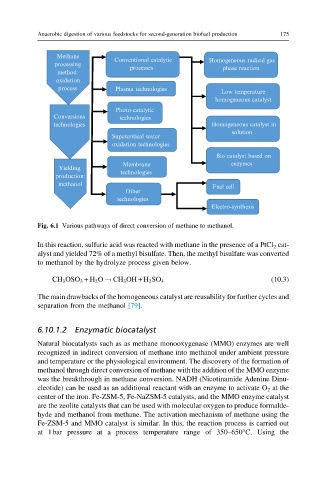

Fig. 6.1 Various pathways of direct conversion of methane to methanol.

In this reaction, sulfuric acid was reacted with methane in the presence of a PtCl 2 cat-

alyst and yielded 72% of a methyl bisulfate. Then, the methyl bisulfate was converted

to methanol by the hydrolyze process given below.

CH 3 OSO 3 +H 2 O ! CH 3 OH + H 2 SO 4 (10.3)

The main drawbacks of the homogeneous catalyst are reusability for further cycles and

separation from the methanol [79].

6.10.1.2 Enzymatic biocatalyst

Natural biocatalysts such as as methane monooxygenase (MMO) enzymes are well

recognized in indirect conversion of methane into methanol under ambient pressure

and temperature or the physiological environment. The discovery of the formation of

methanol through direct conversion of methane with the addition of the MMO enzyme

was the breakthrough in methane conversion. NADH (Nicotinamide Adenine Dinu-

cleotide) can be used as an additional reactant with an enzyme to activate O 2 at the

center of the iron. Fe-ZSM-5, Fe-NaZSM-5 catalysts, and the MMO enzyme catalyst

are the zeolite catalysts that can be used with molecular oxygen to produce formalde-

hyde and methanol from methane. The activation mechanism of methane using the

Fe-ZSM-5 and MMO catalyst is similar. In this, the reaction process is carried out

at 1bar pressure at a process temperature range of 350–650°C. Using the