Page 329 - Advances in Eco-Fuels for a Sustainable Environment

P. 329

Thermal depolymerization of biogas digestate 285

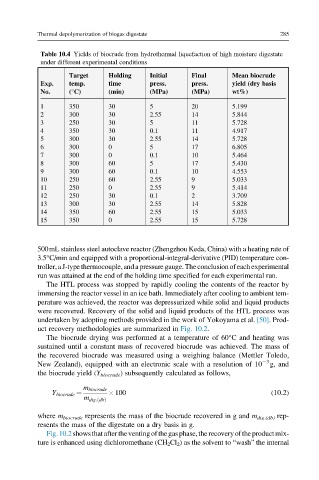

Table 10.4 Yields of biocrude from hydrothermal liquefaction of high moisture digestate

under different experimental conditions

Target Holding Initial Final Mean biocrude

Exp. temp. time press. press. yield (dry basis

No. (°C) (min) (MPa) (MPa) wt%)

1 350 30 5 20 5.199

2 300 30 2.55 14 5.844

3 250 30 5 11 5.728

4 350 30 0.1 11 4.917

5 300 30 2.55 14 5.728

6 300 0 5 17 6.805

7 300 0 0.1 10 5.464

8 300 60 5 17 5.430

9 300 60 0.1 10 4.553

10 250 60 2.55 9 5.033

11 250 0 2.55 9 5.414

12 250 30 0.1 2 3.709

13 300 30 2.55 14 5.828

14 350 60 2.55 15 5.033

15 350 0 2.55 15 5.728

500mL stainless steel autoclave reactor (Zhengzhou Keda, China) with a heating rate of

3.5°C/min and equipped with a proportional-integral-derivative (PID) temperature con-

troller,a J-type thermocouple,anda pressure gauge.Theconclusionofeachexperimental

run was attained at the end of the holding time specified for each experimental run.

The HTL process was stopped by rapidly cooling the contents of the reactor by

immersing the reactor vessel in an ice bath. Immediately after cooling to ambient tem-

perature was achieved, the reactor was depressurized while solid and liquid products

were recovered. Recovery of the solid and liquid products of the HTL process was

undertaken by adopting methods provided in the work of Yokoyama et al. [50]. Prod-

uct recovery methodologies are summarized in Fig. 10.2.

The biocrude drying was performed at a temperature of 60°C and heating was

sustained until a constant mass of recovered biocrude was achieved. The mass of

the recovered biocrude was measured using a weighing balance (Mettler Toledo,

New Zealand), equipped with an electronic scale with a resolution of 10 3 g, and

the biocrude yield (Y biocrude ) subsequently calculated as follows,

m biocrude

Y biocrude ¼ 100 (10.2)

m dig: dbð

Þ

where m biocrude represents the mass of the biocrude recovered in g and m dig.(db) rep-

resents the mass of the digestate on a dry basis in g.

Fig.10.2showsthataftertheventingofthegasphase,therecoveryoftheproductmix-

ture is enhanced using dichloromethane (CH 2 Cl 2 ) as the solvent to “wash” the internal