Page 399 - Advances in Eco-Fuels for a Sustainable Environment

P. 399

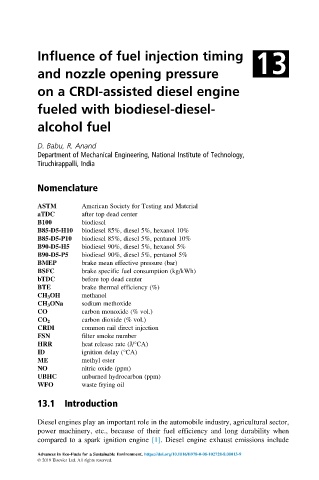

Influence of fuel injection timing 13

and nozzle opening pressure

on a CRDI-assisted diesel engine

fueled with biodiesel-diesel-

alcohol fuel

D. Babu, R. Anand

Department of Mechanical Engineering, National Institute of Technology,

Tiruchirappalli, India

Nomenclature

American Society for Testing and Material

ASTM

after top dead center

aTDC

biodiesel

B100

biodiesel 85%, diesel 5%, hexanol 10%

B85-D5-H10

biodiesel 85%, diesel 5%, pentanol 10%

B85-D5-P10

biodiesel 90%, diesel 5%, hexanol 5%

B90-D5-H5

biodiesel 90%, diesel 5%, pentanol 5%

B90-D5-P5

brake mean effective pressure (bar)

BMEP

brake specific fuel consumption (kg/kWh)

BSFC

before top dead center

bTDC

brake thermal efficiency (%)

BTE

methanol

CH 3 OH

sodium methoxide

CH 3 ONa

carbon monoxide (% vol.)

CO

carbon dioxide (% vol.)

CO 2

common rail direct injection

CRDI

filter smoke number

FSN

heat release rate (J/°CA)

HRR

ignition delay (°CA)

ID

methyl ester

ME

nitric oxide (ppm)

NO

unburned hydrocarbon (ppm)

UBHC

waste frying oil

WFO

13.1 Introduction

Diesel engines play an important role in the automobile industry, agricultural sector,

power machinery, etc., because of their fuel efficiency and long durability when

compared to a spark ignition engine [1]. Diesel engine exhaust emissions include

Advances in Eco-Fuels for a Sustainable Environment. https://doi.org/10.1016/B978-0-08-102728-8.00013-9

© 2019 Elsevier Ltd. All rights reserved.