Page 135 - Advances in Textile Biotechnology

P. 135

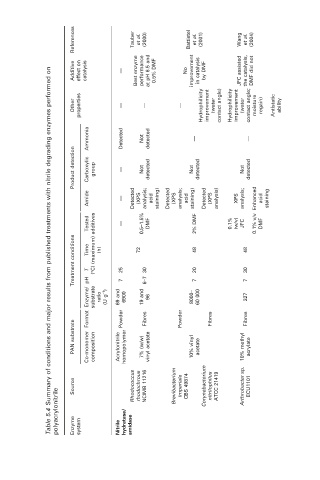

References Tauber et al. (2000) Battistel et al. (2001) Wang et al. (2004)

Additive effect on catalysis — Best enzyme performance at pH 6.5 and 0.5% DMF No improvement in catalysis by DMF JFC assisted DMF did not

Table 5.4 Summary of conditions and major results from published treatments with nitrile degrading enzymes performed on

Other properties — — — Hydrophilicity improvement (water contact angle) Hydrophilicity improvement (water contact angle; the catalysis, moisture regain) Antistatic ability

Ammonia Detected Not detected — —

Product detection Carboxylic group — Not detected Not detected Not detected

Amide — Detected (XPS analysis; acid staining) Detected (XPS analysis; acid staining) Detected (XPS analysis) XPS analysis; Enhanced acid staining

Tested (maximum) additives — 0.5–1.5% DMF 2% DMF 0.1% (w/v) JFC 0.1% v/v DMF

Treatment conditions Time T (°C) (h) 25 72 30 48 20 48 30

Enzyme/ pH substrate ratio (U g −1 ) 69 and 7 6900 19 and 6–7 96 8000– 7 60 000 7 327

Format Powder Fibres Powder Fibres Fibres

PAN substrate Co-monomer composition Acrylonitrile homopolymer 7% (w/w) vinyl acetate 10% vinyl acetate 10% methyl acrylate

Source Rhodococcus rhodochrous NCIMB 11216 Brevibacterium imperiale CBS 49874 Corynebacterium nitrilophilus ATCC 21419 Arthrobacter sp. ECU1101

polyacrylonitrile Enzyme system Nitrile hydratase/ amidase