Page 165 - Advances in bioenergy the sustainability challenge

P. 165

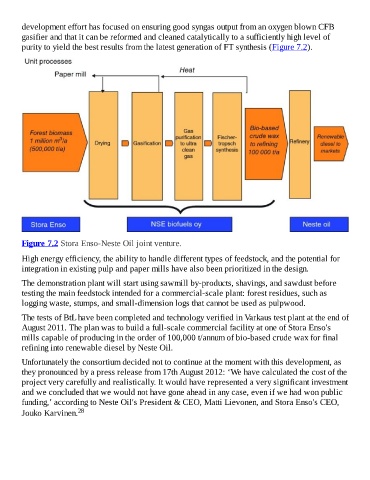

development effort has focused on ensuring good syngas output from an oxygen blown CFB

gasifier and that it can be reformed and cleaned catalytically to a sufficiently high level of

purity to yield the best results from the latest generation of FT synthesis (Figure 7.2).

Figure 7.2 Stora Enso-Neste Oil joint venture.

High energy efficiency, the ability to handle different types of feedstock, and the potential for

integration in existing pulp and paper mills have also been prioritized in the design.

The demonstration plant will start using sawmill by-products, shavings, and sawdust before

testing the main feedstock intended for a commercial-scale plant: forest residues, such as

logging waste, stumps, and small-dimension logs that cannot be used as pulpwood.

The tests of BtL have been completed and technology verified in Varkaus test plant at the end of

August 2011. The plan was to build a full-scale commercial facility at one of Stora Enso's

mills capable of producing in the order of 100,000 t/annum of bio-based crude wax for final

refining into renewable diesel by Neste Oil.

Unfortunately the consortium decided not to continue at the moment with this development, as

they pronounced by a press release from 17th August 2012: ‘We have calculated the cost of the

project very carefully and realistically. It would have represented a very significant investment

and we concluded that we would not have gone ahead in any case, even if we had won public

funding,’ according to Neste Oil's President & CEO, Matti Lievonen, and Stora Enso's CEO,

Jouko Karvinen. 28