Page 196 - Aeronautical Engineer Data Book

P. 196

Aircraft design and construction 159

Electrical

power

Bulk cargo

belt loader Fuel truck

Galley/cabin

service

Bulk cargo train

Lavatory

service Galley/cabin

service

Tow

tractor

Passenger boarding Portable

bridge Lavatory water truck

service

Engine Ground air

air start conditioning

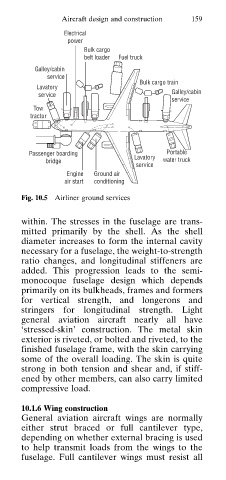

Fig. 10.5 Airliner ground services

within. The stresses in the fuselage are trans

mitted primarily by the shell. As the shell

diameter increases to form the internal cavity

necessary for a fuselage, the weight-to-strength

ratio changes, and longitudinal stiffeners are

added. This progression leads to the semi-

monocoque fuselage design which depends

primarily on its bulkheads, frames and formers

for vertical strength, and longerons and

stringers for longitudinal strength. Light

general aviation aircraft nearly all have

‘stressed-skin’ construction. The metal skin

exterior is riveted, or bolted and riveted, to the

finished fuselage frame, with the skin carrying

some of the overall loading. The skin is quite

strong in both tension and shear and, if stiff

ened by other members, can also carry limited

compressive load.

10.1.6 Wing construction

General aviation aircraft wings are normally

either strut braced or full cantilever type,

depending on whether external bracing is used

to help transmit loads from the wings to the

fuselage. Full cantilever wings must resist all