Page 214 - Air Pollution Control Engineering

P. 214

04_chap_Wang.qxd 05/05/2004 1:15 pm Page 193

Electrostatistic Precipitation 193

corrosion include the outer shell walls, the roof plate, the collecting plate surfaces, the

high-voltage system, the hoppers, the access doors, the expansion joints, and the test

ports. Good design and proper maintenance with an understanding of common corro-

sion processes and preventive measures as outlined in Hall and Katz (36) can provide

viable equipment with long life in service.

6. EXPECTED FUTURE DEVELOPMENTS

Among the candidates for upgrading conventional ESPs are advanced digital voltage

controls, flue gas conditioning, intermittent energization, temperature-controlled

precharging, wide plate spacing, and positive energizition of corona electrodes for

hot-side ESPs. For future developments, the following expected emphases in ESP

development are forecast over the next few years:

1. Use of computer models for precipitator design and performance analysis

2. Derivation of a valid theory whereby the relative importance of the different factors is

reflected directly in the precipitator equations

3. Reduction of the size and cost of a precipitator required for a specific duty

4. Use of wet precipitators in controlling fine particles

5. Design toward even higher efficiency, particularly in the collection of small particles,

which is generally the main justification for using an electrostatic precipitator

6. Use of the electrostatic precipitation process for newer industrial processes such as coal

gasification, gas turbine, and magneto-hydrodynamic (MHD) power generation

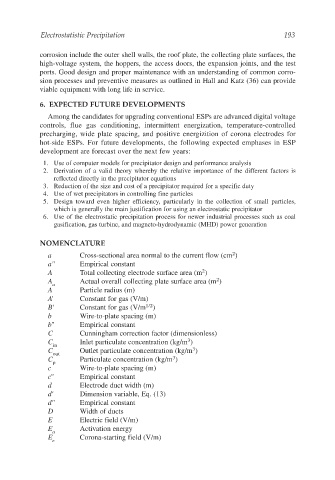

NOMENCLATURE

2

a Cross-sectional area normal to the current flow (cm )

a" Empirical constant

2

A Total collecting electrode surface area (m )

2

A Actual overall collecting plate surface area (m )

a

A Particle radius (m)

A' Constant for gas (V/m)

1/2

B' Constant for gas (V/m )

b Wire-to-plate spacing (m)

b" Empirical constant

C Cunningham correction factor (dimensionless)

3

C Inlet particulate concentration (kg/m )

in

3

C Outlet particulate concentration (kg/m )

out

3

C Particulate concentration (kg/m )

p

c Wire-to-plate spacing (m)

c" Empirical constant

d Electrode duct width (m)

d' Dimension variable, Eq. (13)

d'' Empirical constant

D Width of ducts

E Electric field (V/m)

E Activation energy

a

E Corona-starting field (V/m)

e