Page 371 - Air Pollution Control Engineering

P. 371

08_chap_wang.qxd 05/05/2004 4:25 pm Page 348

348 Lawrence K. Wang et al.

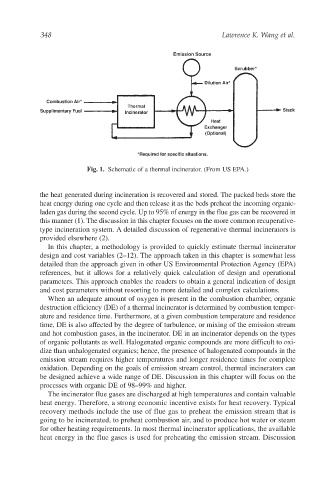

Fig. 1. Schematic of a thermal incinerator. (From US EPA.)

the heat generated during incineration is recovered and stored. The packed beds store the

heat energy during one cycle and then release it as the beds preheat the incoming organic-

laden gas during the second cycle. Up to 95% of energy in the flue gas can be recovered in

this manner (1). The discussion in this chapter focuses on the more common recuperative-

type incineration system. A detailed discussion of regenerative thermal incinerators is

provided elsewhere (2).

In this chapter, a methodology is provided to quickly estimate thermal incinerator

design and cost variables (2–12). The approach taken in this chapter is somewhat less

detailed than the approach given in other US Environmental Protection Agency (EPA)

references, but it allows for a relatively quick calculation of design and operational

parameters. This approach enables the readers to obtain a general indication of design

and cost parameters without resorting to more detailed and complex calculations.

When an adequate amount of oxygen is present in the combustion chamber, organic

destruction efficiency (DE) of a thermal incinerator is determined by combustion temper-

ature and residence time. Furthermore, at a given combustion temperature and residence

time, DE is also affected by the degree of turbulence, or mixing of the emission stream

and hot combustion gases, in the incinerator. DE in an incinerator depends on the types

of organic pollutants as well. Halogenated organic compounds are more difficult to oxi-

dize than unhalogenated organics; hence, the presence of halogenated compounds in the

emission stream requires higher temperatures and longer residence times for complete

oxidation. Depending on the goals of emission stream control, thermal incinerators can

be designed achieve a wide range of DE. Discussion in this chapter will focus on the

processes with organic DE of 98–99% and higher.

The incinerator flue gases are discharged at high temperatures and contain valuable

heat energy. Therefore, a strong economic incentive exists for heat recovery. Typical

recovery methods include the use of flue gas to preheat the emission stream that is

going to be incinerated, to preheat combustion air, and to produce hot water or steam

for other heating requirements. In most thermal incinerator applications, the available

heat energy in the flue gases is used for preheating the emission stream. Discussion