Page 263 - Air pollution and greenhouse gases from basic concepts to engineering applications for air emission control

P. 263

8.3 Thermochemical Conversion of Fuels 239

Catalytic Catalytic

Ethanol Methanol Gasoline

conversion conversion

Catalytic Catalytic

conversion conversion

Fischer-tropsch

Water-gas

H Syngas

2 shift

Fischer-tropsch

Catalytic

Synthesis Isosynthesis

Alcohols i-C Diesel

4

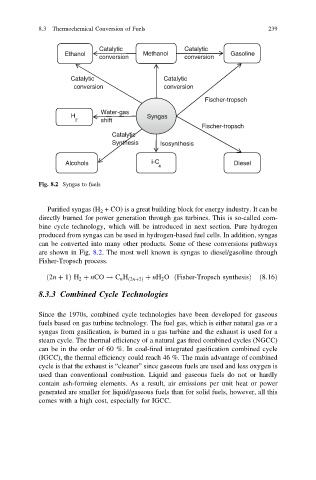

Fig. 8.2 Syngas to fuels

Purified syngas (H 2 + CO) is a great building block for energy industry. It can be

directly burned for power generation through gas turbines. This is so-called com-

bine cycle technology, which will be introduced in next section. Pure hydrogen

produced from syngas can be used in hydrogen-based fuel cells. In addition, syngas

can be converted into many other products. Some of these conversions pathways

are shown in Fig. 8.2. The most well known is syngas to diesel/gasoline through

Fisher-Tropsch process.

ð 2n þ 1Þ H 2 þ nCO ! C n H ð2nþ2Þ þ nH 2 O ð Fisher-Tropsch synthesisÞ ð8:16Þ

8.3.3 Combined Cycle Technologies

Since the 1970s, combined cycle technologies have been developed for gaseous

fuels based on gas turbine technology. The fuel gas, which is either natural gas or a

syngas from gasification, is burned in a gas turbine and the exhaust is used for a

steam cycle. The thermal efficiency of a natural gas fired combined cycles (NGCC)

can be in the order of 60 %. In coal-fired integrated gasification combined cycle

(IGCC), the thermal efficiency could reach 46 %. The main advantage of combined

cycle is that the exhaust is “cleaner” since gaseous fuels are used and less oxygen is

used than conventional combustion. Liquid and gaseous fuels do not or hardly

contain ash-forming elements. As a result, air emissions per unit heat or power

generated are smaller for liquid/gaseous fuels than for solid fuels, however, all this

comes with a high cost, especially for IGCC.